Learning Task 1

Describe Manholes

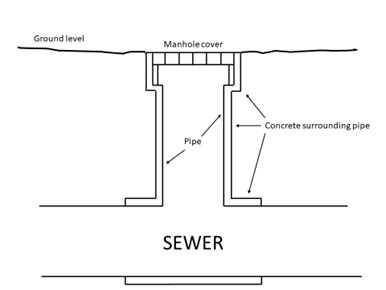

A manhole is a composite or concrete chamber installed at specific intervals along sewer lines, that allow access to the pipes entering and exiting them. Sometimes referred to as inspection chambers, manholes allow inspection, cleaning, and maintenance of sewers without needing to dig them up. They are normally installed at every bend, junction, change of gradient or change of diameter of the sewer. The sewer line between any two manholes is normally laid straight with consistent gradient to minimize the chance of blockages forming at any point between manholes.

Types of Manholes

Manhole types are mainly classified into two categories, which are:

- Based on depth

- Based on construction material

Manholes based on depth

Using overall depth as the factor, manholes are further classified into three categories, these being:

- shallow manholes

- normal manholes, and

- deep manholes

Shallow manholes

Manholes with a depth of 0.75m to 0.9m (2.5 to 3 ft) are called shallow manholes. They are used where the expected amount of traffic over them is low and, consequently, the piping between them is at relatively shallow depths. These manholes can be either round or rectangular in shape and are sometimes referred to as inspection chambers.

Normal manholes

A manhole with an overall depth greater than 0.9m (3 ft) but not more than 2m (6 ft) is called a normal manhole. These manholes typically have a thick cover to support heavy loads over them and, similar to the shallow variety, are either round or square in shape.

Deep manholes

Deep manholes are those with an overall depth of more than 2m (6 ft). These types of manholes are mainly circular in shape and consist of multiple “stacked” sections rather than being one-piece like the shallow or normal manholes.

Manholes based on construction material

Depending on the construction material used, manholes fall into three categories, which are:

- precast concrete manholes

- plastic manholes, and

- fiberglass manholes

Precast concrete manholes

This type of manhole is precast (constructed off-site) and is the predominant style that is used worldwide. It has two steel cable loops embedded in the concrete and protruding out of opposite sides of each section, used for lifting it. They may also have anodized steel rungs embedded to form a self-contained ladder for easier access and egress. Runged sections are rotated so that the rungs are aligned vertically. Precast concrete manholes are available with or without a poured bottom.

Plastic manholes

Plastic manholes are made of polyethene material, which makes them lighter than the concrete versions, allowing for possible placement by hand. They come in various thicknesses and the walls can be either smooth or ribbed. They normally have a bottom to them for structural integrity. Once buried, they normally won’t be affected by ultraviolet rays from the sun and so should last many years. Plastic manholes do not require much maintenance and are highly resistant to the effects of corrosive liquids and soils.

Fiberglass manholes

Like plastic manholes, fiberglass manholes are lightweight, durable, and easier to handle than the concrete versions. Also like the plastic varieties, they commonly have a bottom built into them and generally have more strength than the plastic versions but also tend to be more expensive than plastic. Pipe penetrations are accomplished in a similar fashion to that of the plastic manholes.

Manhole covers

Manholes have lids that normally have a smaller opening built into them for access to the manhole. If the lid is flat, the smaller opening is cast eccentrically into the lid, allowing the lid to be rotated to align the smaller opening with the self-contained ladder below it. Tapered precast sections are also available for the same purpose, as seen below.

Traditionally, manhole covers are constructed of cast iron, concrete, or even a combination of the two. These materials are preferred due to specific qualities like durability, cost, and being heavy enough to stay in place without needing a locking mechanism. However, technology has led to various alternative manhole cover materials like composites, fiberglass, and plastic. Recessed type covers are used for residential projects and service industry projects like hospitals, hotels, malls, etc. Ductile iron covers are often used for airports, docks, roads, and pedestrian walkways where long lifespans in heavy traffic areas is required. Solid top covers are preferred in industrial areas and heavy-duty manufacturing workshops.

Applications

While manholes were initially meant to provide workers with access to pipes and other underground utilities, they are often used for equipment access as well. They can be an access point for an underground public utility such as an underground storm reservoir or lift station, allowing inspection, maintenance, and system upgrades. Most underground services utilize manholes, including water, sewers, telephone, electricity, storm drains, district heating, and gas. Work crews can lower inspection cameras into manholes to gather CCTV footage to assist in determining the need for cleaning and routine maintenance. Manholes also allow the placement and use of remotely controlled equipment. This keeps people above ground and immune from the possible safety and cost implications of entering a confined space that may contain fumes, bacteria, debris, and sewage flows.

Manhole Locations

Indoor Manholes

Although mainly used outdoors, manholes are sometimes installed inside commercial buildings to allow access to services such as underground electrical cables. Using this type of manhole, sometimes referred to as a work chamber, cable chamber or vault, an electrician can enter it to inspect and service existing circuits or to add more cables to service new equipment.

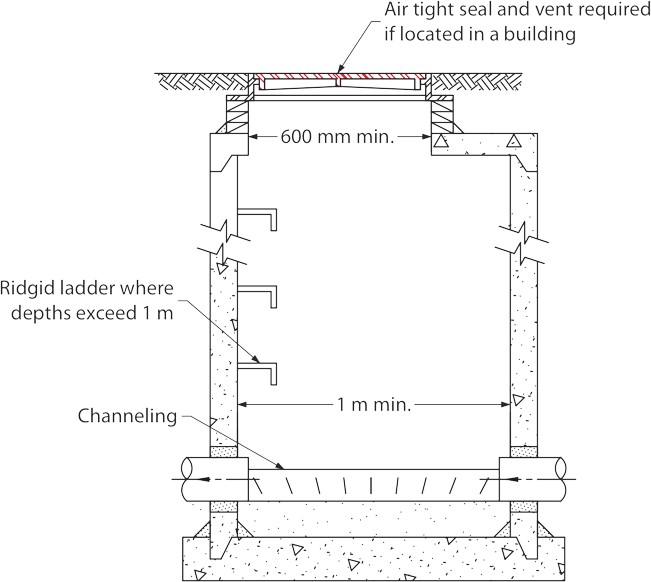

Clause 2.4.7.3. (1) (c) of the NPC requires that a manhole installed inside a building needs a vent to the exterior, with Sentence 2.5.7.6. (1) stating that the vent must be a minimum size of 2 inches. The codes don’t specify what the manhole is used for, only that a vent is required if it is indoors.

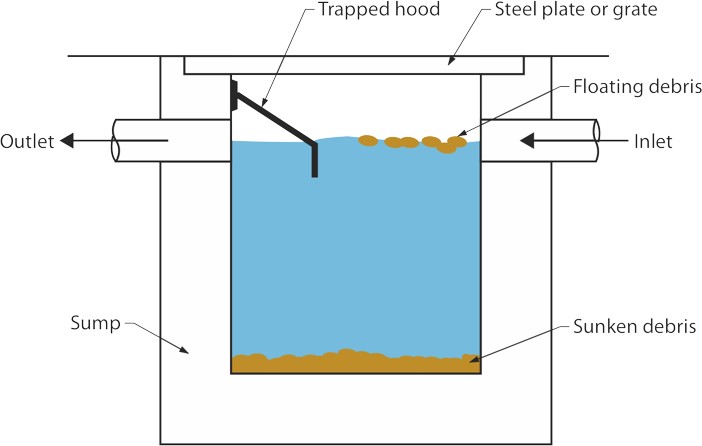

Storm Manholes

Storm manholes are used in conjunction with catch basins to move untreated stormwater to disposal areas such as ditches or larger bodies of water. Storm manholes can have multiple inlet pipes at varying elevations and usually have only one outlet pipe. Because storm manholes are usually installed with a sealed bottom, there will be a standing water level within it. At the outlet, a hood or a downturned 90-degree elbow with its inlet below the standing water level prevents floating material from entering the outlet pipe. A backwater valve is sometimes installed at the outlet as well. The backwater valve prevents reverse flow back into the manhole caused by downstream drainage issues such as overloading.

Sanitary Manholes

Sanitary manholes are used in conjunction with gravity or pressure fed piping systems engineered to move raw sewage to treatment plants. Manholes are commonly placed every 100 – 120m (300-400 ft) in sewer collecting lines, but this may vary depending on municipalities, engineers, codes, and design standards. Sanitary sewer manholes are most commonly made of precast concrete. They have concrete bottoms into which are sculpted channels for moving raw sewage, containing solids, from multiple inlets into a single outlet. The inlets and outlet are at elevations that differ only by the amount of grade required to allow flow by gravity between them.

Specialty Manhole Types

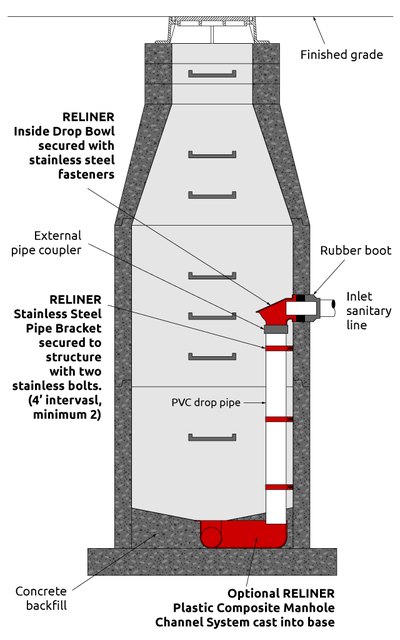

Drop Manhole

As previously stated, the flow through a sanitary manhole must be channeled, which means the entry and exit pipe elevations must be almost the same. A drop manhole describes the piping arrangement sometimes provided at the junction point of a high-level sewer inlet and a low-level main sewer outlet. The use of a drop manhole avoids an unnecessary steep gradient of the sewer piping feeding into it and thus reduces the quantity of earthwork required, while it also negates the possibilities of sewage being thrown onto personnel entering the working chamber of the manhole.

Lamp Manhole

A lamp manhole is a small opening on a sewer that is extended vertically to the ground’s surface for the purpose of lowering a lamp or light inside it. The lamp holes were provided at places where inspection of the flow through the sewer was necessary due to bends in the sewer or where there was greater length between manholes than desired due to difficulty in installing or locating a “standard” manhole. A lamp hole could also be used as a flushing point if needed, and if its top cover was perforated, it could assist in the ventilation of the sewer.

Although existing lamp manholes can be found in some jurisdictions, they are not referenced in either the NPC nor the BCPC as such and their allowable use is debatable. Sentence 2.2.6.2. (1) of the NPC alludes to the existence of “maintenance holes” and if a lamp manhole could be categorized as such, it might be allowable by code.

Media Attributions

- Figure 1 Tapered precast concrete barrel sections © Kohnen Concrete Products, Inc. Used with permission.

- Figure 2 Manhole lid and cover by SuSanA Secretariat is licensed under a CC BY 2.0 licence.

- Figure 3 Plastic manhole cover by Greg Wirachowsky is licensed under a CC BY-NC-SA licence.

- Figure 4 Triple-sealed access cover for interior manhole © Kent Stainless. Used with permission.

- Figure 5 Storm manhole by ITA is licensed under a CC BY-NC-SA licence.

- Figure 6 Sanitary manhole by ITA is licensed under a CC BY-NC-SA licence.

- Figure 7 Manhole components © Reliner, used with permission.

- Figure 8 Lamp manhole by Greg Wirachowsky is licensed under a CC BY-NC-SA licence.