Competency B1: Select Regulators, Valves, and Valve Train Components

Learning Task 2

Describe Gas Valve Train

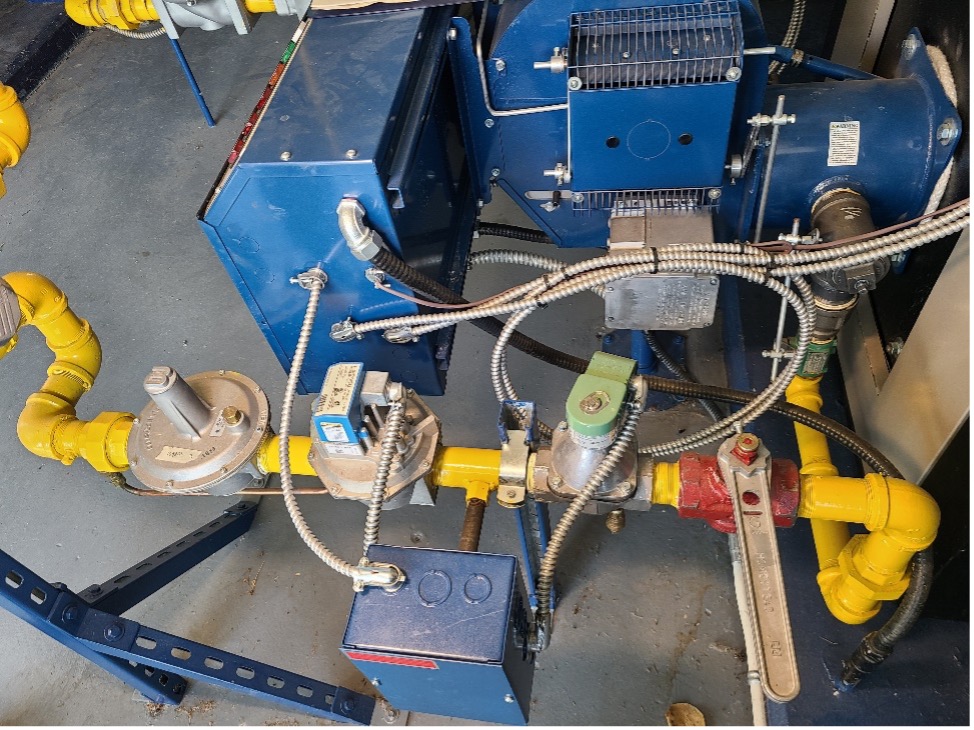

The series of controls and components from the appliance main shut-off valve to the appliance burner is called the valve-train or manifold assembly. The components of the valve train are used to manually and automatically start, stop and regulate the gas flow to the appliance. On larger gas appliances, generally over 400 MBH, the valve train components downstream of the manual shut-off valve (Figure 12) will be field assembled as they are not an integral part of the appliance. For these installations the requirement for valve train components and their assembly are identified in the separate CSA B149.3 gas code.

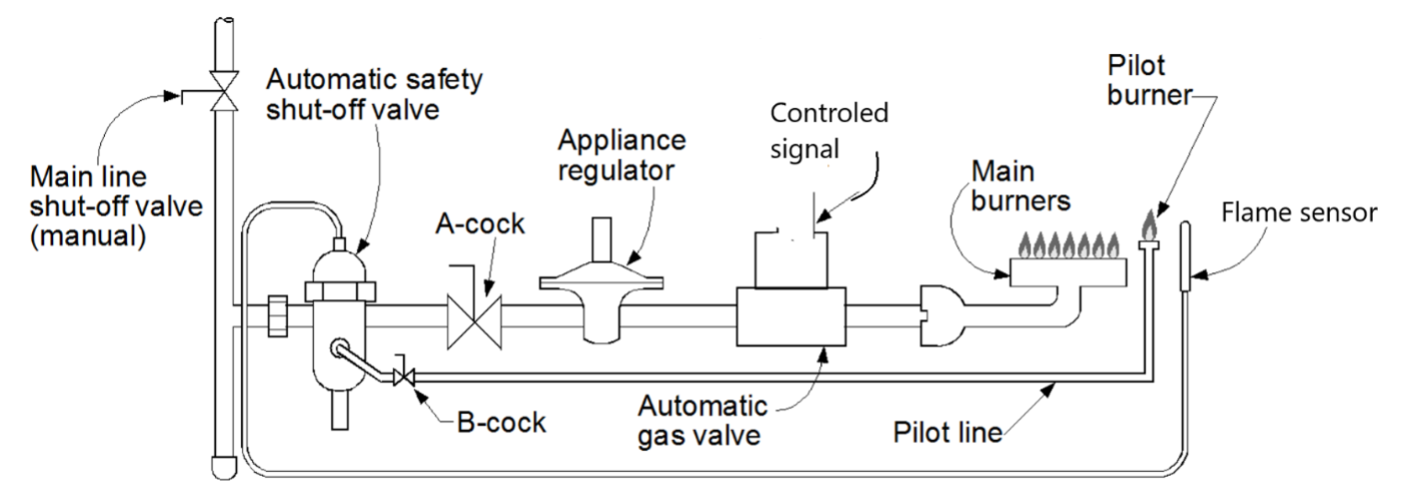

For installations under 400MBH the valve train assembly is typically supplied and preassembled as part of the appliance. Although manufactures appliance valve trains will vary in how they are assembled, they will all have the components shown in Figure 13 in one form or another. This diagram is used as in introduction because it shows all of the components as separate parts, whereas on modern appliance many of these components are combined into one valve. body.

The valve train components from the manual shut-off valve will include:

- Automatic safety shut-off valve; will turn off all the gas to the appliance in the event of burner failure. If the automatic safety shut-off valve stops the flow of gas to both the main burner and the pilot burner it is referred to as 100% safe.

- B-cock; can be a ball valve but, is usually a needle-type valve included within a combination valve body. It is used to isolate as well as throttle the volume of flow to the pilot burner assembly in order to adjust the pilot flame.

- A-Cock; a manual shut-off valve that is used to isolate the components downstream to enable servicing while still allowing gas to flow to the pilot. It does not regulate either flow or pressure, just opens and closes the gas line.

- Appliance regulator; maintains a constant gas pressure to the burner(s) over a sometimes fluctuating gas inlet pressure and a possible modulating burner gas flow. This assures a constant, even flame at the main burners. Regulators will be looked at in greater detail in Learning Task 3.

- Automatic gas valve; a valve normally energized by a 24-volt alternating current (AC), but may be line voltage (120 V) or millivoltage (thousandths of a volt). It is usually wired in series with a sensing control (thermostat, aquastat, or pressuretrol) which automatically activates the appliance as needed. It can also be a non -electric valve activated by a mechanical heat sensing controller.

Now complete Self-Test 2 and check your answers.

Now complete Self-Test 2 and check your answers.

Self-Test 2

Self-Test 2

Media Attributions

- Figure 12. “Field assembled valve train” by Rod Lidstone is licensed under a CC BY-NC-SA licence.

- Figure 13. “Valve train assembly” – The source for this image is unknown. It is being used for non-commercial, educational purposes. To receive credit for this image, please reach out to the publisher.