Competency B4: Install Air Supply Systems for Fuel Gas Appliances

Learning Task 2

Code Requirements For Gas Appliance Air Supply

In this learning task, we will examine the air supply gas code requirements in the gas code. These interpretations are not legal; the clauses contained in the code must be referenced as to the exact legal meaning.

For safe and efficient operation of gas appliances, the Gas Codes require that you supply enough air for combustion, venting, and ventilation of the mechanical room. The Gas Code will specify various methods of meeting the air requirements. You must clearly understand Code requirements before you can determine the correct sizes of air supply ducts or openings.

Clauses 8.2 to 8.7 of the CSA B149.1 gas code, identify the requirements for the installation and sizing of passive combustion air supply openings and ducts. As previously mentioned the gas code requirements for venting and air supply do not apply to direct vent appliances as these have their own independent air supply and exhaust systems which are sized according to the manufactures’ literature.

When determining the passive air supply requirements for gas appliances, the B149.1 Gas code separates installations into two categories:

- Low Volume Installations – installations up to and including 400000 Btuh (120 kW)

- High Volume Installations – installations over 400000 Btuh (120 kW).

The Gas Code also allows for air to be supplied mechanically. This usually requires a ducted system with some type of fan to force movement of the air supply. The National Code is not specific about forced air flow design other than to say “sufficient air flow shall be demonstrated”. Additionally, in British Columbia there is a Variation to the National Code that requires the fan supply at least 30 ft3 of outside air for each 1000 Btuh of gas supplied to the burners, when the appliances served have draft control devices

Passive air supply requirements for low volume installations

The air supply requirements for gas appliances with a total input of up to and including 400000 Btu/h or 120 kW. are determined from clauses 8.2 and 8.3. The tables used within clause 8.2 will indicate the minimum size of the required air supply in relation to the combined input of the gas appliances.

As you read the code requirements of Clause 8.2 you will be required to identify key points related to the type of equipment and the structure of the building housing it. These include:

- appliance type and location

- building construction

- appliance type of draft control.

Appliance type and location

The Code states that clause 8.2 applies to the air supply for central heating furnaces, boilers, and hot water heaters. However, clause 8.1.5 also indicates, that the same care and attention must be taken to ensure that all gas-burning appliances and equipment have a clean and adequate air supply.

Any interference with the air supply is prohibited. For example, the required air supply values in the code are only the required air supply for the gas appliances and do not account for any other air being consumed or removed from the space around the appliances or equipment. When there is more than one gas appliance in the same room the air supply will be ducted to the appliance having the largest input.

Building construction

The current construction methods used in residential and commercial buildings will typically create a tight building envelope. Code clause 8.2.1 gives two methods of determining whether the building envelope is classified as tight. For sizing examples you may also see tight construction described as, a building that complies with 8.2.1. Another descriptor may be R-2000. If you are in doubt it is always safest to assume the building envelop is tight, (complies to 8.2.1), and the air supply will be sized according to clause 8.2.2.

If a building is not airtight, described as loose, or does not comply to 8.2.1, and the volume is large enough, the air supply may be provided directly from within the structure with no need for ducts or openings to the outside. If the volume is not large enough then an outdoor air supply will be needed just as it was for a tight structure. Consult tables 8.3 and 8.4 in CSA B149.1.

Appliance draft control

One you have established whether or not the appliance(s) are located in a tight or loose structure, you will need to select a sizing table. There are two tables, for each of the building types. The table selection is determined by whether or not the appliance(s) are equipped with a draft control device.

Appliance(s) equipped with draft control devices (draft hood, draft diverter, or barometric draft regulator) require both combustion and dilution air and will be sized from either Table 8.1 (tight construction) or Table 8.3 (loose construction).

Appliance(s) equipped without draft control devices will have a lesser air supply requirement, as they do not require dilution air, will be sized from either Table 8.2 (tight construction) or Table 8.4 (loose construction).

Often equipment with draft control devices and equipment without draft control devices are installed together and take air supply from the same source. In such cases, the required size of air supply opening is based on the greater of either the size required by Table 8.1 or 8.3 using the total input of only those appliances having draft control devices or the size required by Table 8.2 or 8.4 using the total input of all appliances. To help understand this, the steps would be as follows:

- Identify the type of structure and the tables to use.

- Total the input of all equipment with draft control devices.

- Determine the required free area from either Table 8.1 or Table 8.3.

- Total the input of all equipment with and without draft control devices.

- Determine the required free area from either Table 8.2 or Table 8.4.

- Choose the larger of the areas indicated for steps 3 or 5

Low volume sizing examples

Work through the following examples, referencing and confirming each step with the Gas Code

Example 1

What would be the size of an air supply duct serving an 80 MBH hot water boiler and a 50 MBH hot water tank? Both appliances have draft hoods and the building complies with code clause 8.2.1.

Solution:

- Installation totals 130 MBH (80 MBH + 50 MBH) and therefore would be classified as low volume and Code clause 8.2 applies.

- Is the structure tight or loose?

Since this example problem complies with 8.2.1, it would be considered a tight structure therefore 8.2.2 is the code clause that specifies the sizing method to be used for low volume airtight installations.

- Do the appliances have draft control or not?

Both appliances in this example have draft control devices and therefore the air supply would be sized from Table 8.1. When using Table 8.1, take the total input of the appliances and refer to the left hand column of the table. Select an input equal to or greater than the input of our appliances (we would rather give it more air than not enough air), in this case 150 MBH. The center column of the table lists the minimum unobstructed (or free) area of the air supply. For this example, the minimum free area required for the air supply duct would be 22 in.2

The right hand column is the minimum acceptable round duct size, therefore for an input of 150 MBH, the minimum acceptable round duct size would be 5 inches in diameter

It is worth noting that the round duct column is not an exact conversion from the required free area column. Each acceptable approximate round duct size with covers a range of minimum free area rows.

Example 2

What would be the minimum required free area of a rectangular air supply duct serving two 100 MBH fan-assisted boilers that are not equipped with draft control devices, if the building is considered tight?

Solution:

- Installation totals 200 MBH (100 MBH + 100 MBH) and therefore would be classified as low volume and Code clause 8.2 applies.

- Is the structure tight or loose?

The building is considered an airtight structure therefore 8.2.2 is the code clause that specifies the sizing method to be used for low volume airtight installations.

- Do the appliances have draft control or not?

Both appliances in this example do not have draft control devices and therefore the air supply would be sized from Table 8.2. Since the total input of the appliances in this example is 200 MBH, the air supply duct must be sized using the 200 MBH row. The center column lists the minimum required free area of the air supply duct. For 200 MBH the minimum required free area for our rectangular duct would be 14 in.2

Clause 8.3.2 stipulates that a square or a rectangular duct may be used as an air supply, but it cannot have a dimension of less than 3 inches due to concerns over flow resistance. Therefore the free area can never be less than 9 in.2 when using rectangular duct.

Example 3

A building that complies with code clause 8.2.1, is to contain one 75 MBH gas-fired appliance with a draft hood and one 50 MBH appliance without a draft control device. What would be the minimum required free area of a rectangular air supply duct to these appliances?

Solution:

- Installation totals [latex]125 \text{ MBH} (50 \text{ MBH }+ 75\text{ MBH})[/latex] and therefore would be classified as low volume and Code clause 8.2 applies.

- Is the structure tight or loose?

The building is considered an airtight structure therefore 8.2.2 is the code clause that specifies the sizing method to be used for low volume airtight installations.

- Do the appliances have draft control or not?

This installation contains both types of appliances, one appliance with draft control and one without. Code clause 8.2.2 requires that we must take the appliance with draft control and size the air supply from Table 8.1. Then we would take the total input of all the appliances added together and size the air supply from Table 8.2. Whichever method produces the largest size, would be the size of our air supply.

When the 75 MBH appliance with the draft hood is sized form Table 8.1 the minimum opening is 11 in.2.

When the appliances are added together (125 MBH) and sized from Table 8.2, the free area air supply is 9 in.2. The larger size must be used; therefore, the air supply for this example problem would be 11 in.2.

Example 4

What would be the minimum required free area of a rectangular air supply duct serving on 100 MBH appliance with draft hood located in a large loosely constructed warehouse with a volume of 6500 ft3?

Solution:

- Installation totals 100 MBH and therefore would be classified as low volume and Code clause 8.2 applies.

- Is the structure tight or loose?

The building is considered a loose structure therefore 8.2.5 is the code clause that specifies the sizing method to be used for low volume loose building installations.

In order to use Tables 8.3 or 8.4, the volume of the structure or enclosure must be known. If the building is not air tight and has a large volume to draw from the air supply from the table may indicate “0”, it means that the volume of the structure is large enough to provide the required air supply. If the volume is not large enough the table will indicate the minimum air supply duct from outdoors.

When selecting a volume column for tables 8.3 or 8.4 if the structure volume falls between table values you must round down to the smaller table volume.

- Do the appliances have draft control or not?

The appliances in this example have a draft control device and therefore the air supply would be sized from Table 8.3.

With an appliance input of 100 MBH and a volume of 6500 ft3. Table 8.3 indicates that the required free area of the outdoor air supply, at a volume of 6000 ft3, would be 0 in.2. Therefore, the appliance will be able to draw its air supply from the unrestricted building volume.

Notice on Table 8.3 if the volume of the structure was reduced to any size less than 6000 ft3 an outside air supply of 11 in.2 would be required. It is also worth noting that all of the sizes required as a result of smaller volumes on Table 8.3 are consistent with the air requirements of Table 8.1. This is also true when comparing Table 8.4 to 8.2 for appliances without draft control.

Enclosures in a loose structure (low volume)

When a low volume installation is located within an enclosure (room) within a loose structure (building) you may be able to draw the air supply from the structure by adding openings in a wall between the room and the building. This would enable the entire volume of the building to be used and thereby possibly avoiding the need for an outside air supply into the room. The quality of the building air must be accessed before considering this option.

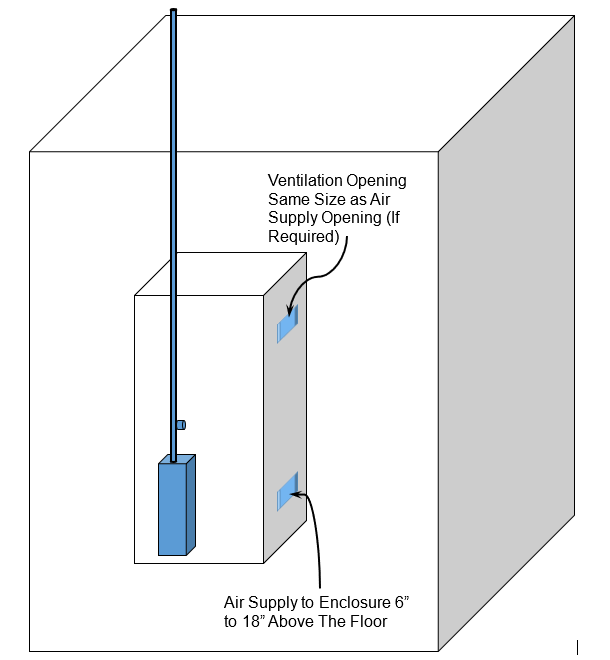

The criteria explained in Clause 8.2.6 is only meant to be applied if the building has sufficient volume to supply the appliance(s). Therefore, the first step is to check that air supply when sized from Table 8.3 or Table 8.4 gives a table value is “0”, indicating that an outdoor air supply is not required as the building has sufficient volume. In these cases, the entire volume of the structure may be used when permanent openings are provided in accordance with Clause 8.2.6 a) and b) (Figure 6).

If you choose to not draw the air supply from the building, then the room will require an appropriately sized outdoor air supply.

Example 5

A mechanical room is located within a warehouse of loose construction. The mechanical room contains a draft hood equipped boiler with an input of 250 MBH. The dimensions of the mechanical room are 15 ft × 10 ft × 10 ft (1500 ft3), and the dimensions of the warehouse are 50 ft × 40 ft × 10 ft (20000 ft3). Size the required air supply opening(s) for this installation?

Solution:

- Installation totals 250 MBH and therefore would be classified as low volume and Code clause 8.2 applies.

- The building is considered a loose structure therefore 8.2.5 is the code clause that specifies the sizing method to be used for low volume loose building installations.

- The appliance in this example has a draft control device and therefore the air supply would be sized from Table 8.3.

The appliance has a rated input of 250 MBH and is equipped with a draft control device. The volume of the enclosure is only 1500 ft3 using this volume table 8.3 indicates an outdoor air supply of 36 in.2 is required

Alternately if we were able to use the volume of the full structure (20000 ft3), Table 8.3 indicates a value of “0”, which means the volume of the structure is sufficient to supply the appliance.

- Code clause 8.2.6 will allow the use of the structure’s volume provided that a permanent opening based on 1 in.2 of free area for every 1000 Btu’s of input is located between 6 inches and 18 inches above the floor. In this case having an input of 250000 Btu’s, we would require a 250 in.2 air supply opening.

Code clause 8.2.6 also indicates that if any of the appliances located in the enclosure have a draft control device, then a ventilation opening is also required and shall be the same size as the air supply opening. The ventilation opening must be located as high as possible in the enclosure to ensure that warm air will exit from the space.

Single water heater air supply

Water heaters seldom operate as continuously as furnaces or boilers. Therefore, the Gas Code stipulate that if a single non-direct vent water heater of 50 MBH or less is installed, an outdoor air supply is not required. This exception only applies if there are no other gas appliances that required an air supply, in which case the load of the water heater must be included in the sizing of the air supply of all appliance in that area.

If the water heater is contained in an enclosure, permanent opening(s) must be provided between the enclosure and the structure. These opening(s) would also be sized and located as described in Code Clause 8.2.6 a) and b).

Passive air supply requirements for high volume installations

The air supply requirements for gas appliances with a total input over 400000 Btu/h or 120 kW. are determined from clause 8.4. Do not try and mix in code requirements from earlier clauses related to low volume installations. The air requirements for high volume installations fall into two categories: ventilation air and combustion/dilution air supply.

Ventilation air

High volume installations require ventilation of the space in which they are installed to remove excess heat or combustion products spilled at the draft hood to ventilate to the outdoors through natural convection. Clause 8.4.1 specifies the criteria for the ventilation air opening.

The ventilation air opening must be a separate building opening from the combustion air opening. It must communicate with outdoors and be located as high as practical within the mechanical room and not within 12 inches (300 mm) of the combustion air opening, this will to ensure that warm air driven by buoyancy forces will exfiltrate from the space.

The size of the ventilation free area opening shall be at least 10% of the size of the air supply free area opening, but can never be less than 10 in.2 (6500 mm2) of free area. Therefore you will need to size the air supply opening first before the ventilation opening size can be determined.

Air supply

As has already been discussed, some appliances will need proportionately more air supply then others due to their additional dilution air requirement. Therefore, just as was the case with low volume installations you will need to first identify whether or not the appliance(s) are equipped with draft control devices. Once this has been determined the appropriate air supply requirements can be selected from one of three options:

- Clause 8.4.2 where all appliances within the space have draft control devices

- Clause 8.4.3 where all appliances within the space do not have draft control devices

- Clause 8.4.4 there is a mixture of appliances with and without draft control devices within the space.

The air supply must come from the outdoors and the free area is determined by the input of the appliances within the room.

Equipment with draft control

For appliance(s) with draft control the area of the air supply shall be at least 1 in.2 for every 7000 Btu’s of input up to and including 1000000 Btu’s, plus 1 in.2 for every 14000 Btu’s in excess of 1000000 Btu’s. For metric calculations use; 310 mm2 for every kW up to and including 293 kW plus 155 mm2 for every kW in excess of 293 kW).

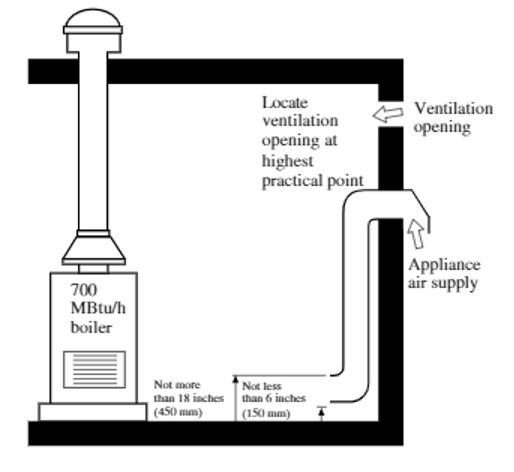

The air supply shall be located not less than 6 in. (150 mm) or more than 18 in. (450 mm) above the mechanical room floor (Figure 7).

Example 6

A mechanical room is equipped with equipped with gas appliances that have a total input of 1400 MBH. All of the appliances have draft control devices. Size the minimum free area for both the air supply and ventilation openings.

Solution:

- The installation totals exceed 400 MBH and therefore are classified as high volume and Code clause 8.4 applies.

- All of the appliances have draft control devices and therefore the air supply would be sized by the method described in code clause 8.4.2.

- 1 in.2 for every 7000 Btu’s up to and including 1000000 Btu’s.

[latex]1\;000\;000 \text{ Btu } \div 7\;000 \dfrac{\text{ Btu}}{\text{ in.}^2} = 142.86 \text{ in.}^2[/latex]

- 1 in.2 for every 14000 Btu’s for anything in excess of 1000000 Btu’s.

[latex]400\;000 \text{ Btu } \div 14\;000 \dfrac{\text{ Btu}}{\text{ in.}^2} = 28.57 \text{ in.}^2[/latex]

- Therefore, the size of the air supply for this installation would be:

[latex]142.86 \text{ in.}^2 + 28.57 \text{ in.}^2 = 171.43 \text{ in.}^2[/latex]

- 1 in.2 for every 7000 Btu’s up to and including 1000000 Btu’s.

- Code clause 8.4.1 states: all ventilation openings shall be at least 10% of the size of the air supply opening but can never be less than 10 in.2 (6500 mm2).

Therefore, the size of the ventilation opening would be:

[latex]171.43 \text{ in.}^2 \times 10\% = 17.143 \text{ in.}^2[/latex]

17.143 in.2 is greater than the minimum allowable size of 10 in.2

Equipment without draft control

Appliances without draft control devices require only combustion air as the venting of such appliances relies on a mechanically driven pressure difference. The size of air supply opening is, therefore, less than that required for appliances with draft control devices.

For appliance(s) without draft controls the free area of the air supply shall be 1 in.2 for every 30000 Btu’s (or 70 mm2 for every kW) of the total input of the power burner(s).

Since these power burners create a mechanical pressure difference through the appliance and will draw in the required combustion air, air supply openings may be located anywhere, provided that these do not interfere with the performance of the ventilation air opening(s).

Example 7

A mechanical room is equipped with gas appliances that have a total input of 1400 MBH. None of the appliances have draft control devices. Size the minimum free area for both the air supply and ventilation openings.

Solution:

- The installation totals exceed 400 MBH and therefore is classified as high volume and Code clause 8.4 applies.

- All of the appliances have power burners without draft control devices and therefore the air supply would be sized by the method described in code clause 8.4.3.

- 1 in.2 for every 30000 Btu’s of total input.

[latex]1\;400\;000 \text{ Btu } \div 30\;000 \dfrac{\text{ Btu}}{\text{ in.}^2} = 46.67 \text{ in.}^2[/latex]

- Therefore, the size of the air supply for this installation would be:

[latex]46.67 \text{ in.}^2[/latex]

- 1 in.2 for every 30000 Btu’s of total input.

- Code clause 8.4.1 states: that all ventilation openings shall be at least 10% of the size of the air supply opening but can never be less than 10 in.2 (6500 mm2).

[latex]46.67 \text{ in.}^2 \times 10\% = 4.667 \text{ in.}^2[/latex]

Since 4.667 in.2 is less than the minimum allowable size of 10 in.2 the size of the ventilation air opening would be 10 in.2

A mix of equipment with and without draft control

When appliances with and without draft control devices are installed, clause 8.4.4 requires that the air supply must be calculated separately for the applicable appliance type. In other words, calculate the requirements for all draft control equipped equipment as per Clause 8.4.2 and calculate the requirements for all of the power burners as per Clause 8.4.3. The cross-sectional area for the two types of appliances can be provided using either separate openings or a single opening with the total area of both requirements. If a single opening is used it must be located as per 8.4.2 to ensure it will properly serve the appliances with draft controls.

Once again, this air supply requirement(s) must be in addition to the air opening for ventilation air.

Example 8

Calculate the free area of the air supply and ventilation openings required for the following installation:

A structure has a mechanical room into which air must be ducted from outdoors. It contains the following appliances:

- Three boilers rated at 400000 Btuh each equipped with a barometric damper.

- Two duct heaters equipped with power burners that are rated at 400000 Btuh each.

- Two storage type hot water tanks rated at 300000 Btuh each. Both tanks are equipped with draft hoods.

Combine into single air supply and ventilation openings with the total area of both requirements.

Solution:

- The installation totals exceed 400 MBH and therefore are classified as high volume and Code clause 8.4 applies.

- Some appliances have draft control and some do not, therefore the air supply would be sized by the method described in code clause 8.4.4.

Total input of the appliances with draft control:

(Boilers) 1200000 Btuh + (Hot water tanks) 600000 Btuh = 1800000 Btuh

- Air supply sized by the method described in code clause 8.4.2:

[latex]1\;000\;000 \text{ Btuh} \div 7\;000 \dfrac{\text{ Btuh}}{\text{in.}^2} = 142.857 \text{ in.}^2[/latex][latex]800\;000 \text{ Btuh } \div 14\;000 \dfrac{\text{Btuh}}{\text{in.}^2} = 57.143 \text{ in.}^2[/latex]

- The area of the air supply required for the appliances with draft control would be:

[latex]142.857 \text{ in.}^2 + 57.143 \text{ in.}^2 = 200 \text{ in.}^2[/latex]

Total input of the appliances without draft control devices:

(Duct heaters) 800000 Btuh

- Air supply sized by the method described in code clause 8.4.3:

[latex]800\;000 \text{ Btuh } \div 30\;000 \dfrac{\text{Btuh}}{\text{in.}^2} = 27 \text{ in.}^2[/latex]

- The area of the air supply required for the appliances without draft control would be:

[latex]27 \text{ in.}^2[/latex]

The total free area of the single air supply opening required for this installation would be:

200 in.2 (with draft control) + 27 in.2 (without draft control) = 227 in.2

- The single ventilation opening required by Code clause 8.4.1 would be:

[latex]227 \text{ in.}^2 \times 10\% = 22.7 \text{ in.}^2[/latex]

22.7 in.2 is greater than the minimum allowable size of 10 in.2.

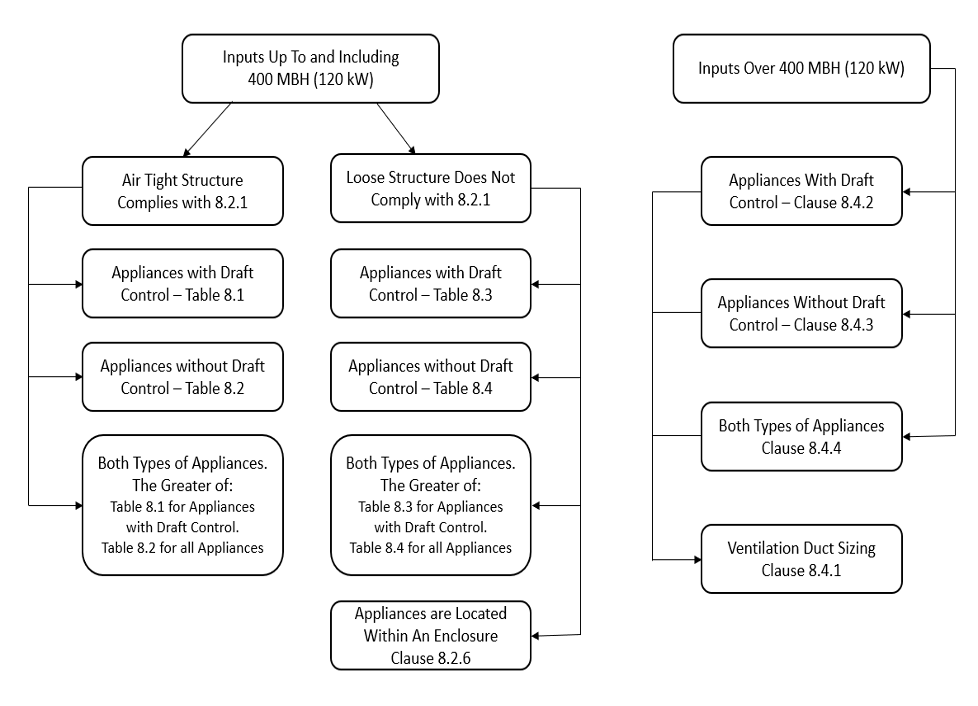

Figure 8 summarizes the clauses and table that relate to sizing air supply openings for gas appliances.

Grilles, louvres, screens and dampers

The air supply inlet openings from outdoors must protect against the entry of wind and rain. This will typically require the addition of grilles, louvers, or dampers. Grilles and louvers create a resistance to air flow; therefore, the grille area will need to be larger than the required free area from the code. The area of the grilles, bars, or slats is subtracted from the area of the opening to attain the free area of the grille.

To help you determine the free area, manufacturers provide charts that list grille efficiencies and/or their respective free areas. Common louver free areas range from 35% to 60% of the wall opening which means they have 65% to 40% obstructed area respectively. For example, the louvered grille shown in Figure 9 measures 300 mm × 400 mm giving it an opening area of 120000 mm2. If the grille has an efficiency of 65%, the free area of the opening with this grille installed will be 120000 × 65% = 78000 mm2 (121 in.2).

In reality though we would typically first know the required free area from our code regulations. Are we would need to calculate what size of louvred opening we would need. In this case the grille area(size) can be calculated by:

[latex]\text{Required free area of the air supply} \div \text{by the grille efficiency} = \text{required grille area}[/latex]

For example: If you were using code table 8.1 with an appliance input of 250 MBH the required free area would be 36 in.2 of free area. If the grille has an efficiency of 60% then

[latex]36 \text{ in.}^2 \div 65\% = 55.385 \text{ in.}^2 \text{minimum grille area}[/latex]

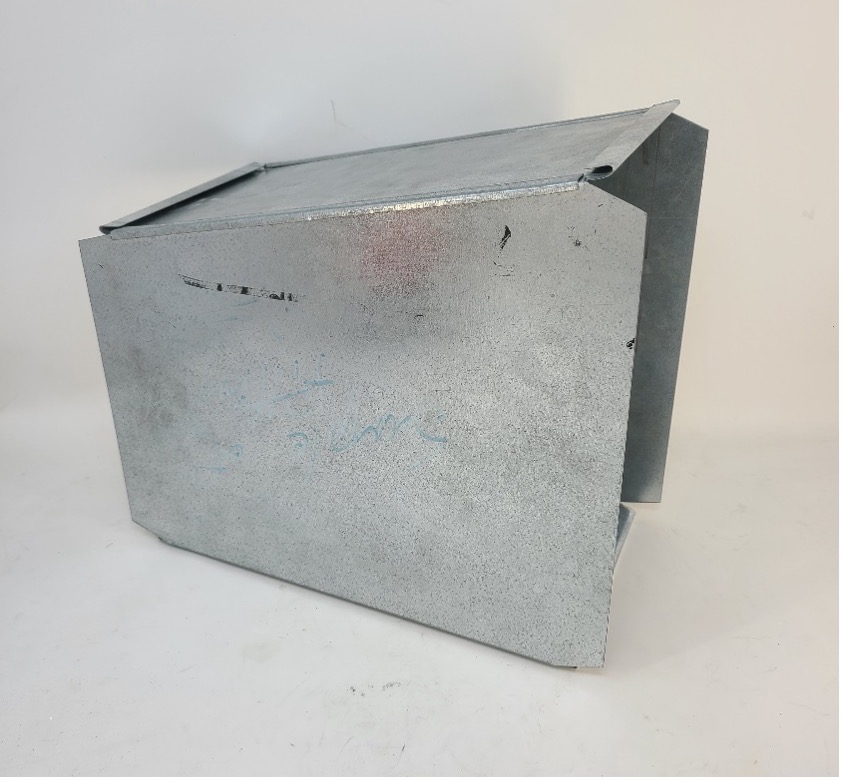

For this installation you could use a reducing transition fitting (Figure 10) at the grille connection, or an oversized duct, with the same size as the grille opening.

Grille design

Part 6 of the National Building Code of Canada requires that any duct or opening leading from the inside to the outside of a building or enclosure must be fitted with corrosion-resistant screens. The Gas code requires that the openings in a fixed louver, grille or screen cannot be smaller than ¼ inch (6 mm) so that small impurities in the air will not block the openings and restrict air flow.

Automatic dampers and louvers are permitted provided that they are interlocked with the appliance(s) burner so that it cannot operate unless they are fully open to ensure proper air supply. Manually operated dampers and manually adjustable louvers are not permitted as these may be accidentally closed.

Now complete Self-Test 2 and check your answers.

Now complete Self-Test 2 and check your answers.

Self-Test 2

Self-Test 2

Media Attributions

- Figure 6. "Enclosure within a loose structure" - The source for this image is unknown. It is being used for non-commercial, educational purposes. To receive credit for this image, please reach out to the publisher.

- Figure 7. "Air supply duct location" by Camosun College is licensed under a CC BY-NC-SA licence.

- Figure 8. "Air supply flow chart" by Camosun College is licensed under a CC BY-NC-SA licence.

- Figure 9. "Metal louvered grille" by Camosun College is licensed under a CC BY-NC-SA licence.

- Figure 10. "Sheet metal rectangular reducer" by Camosun College is licensed under a CC BY-NC-SA licence.

Image Descriptions

Figure 8. "Air supply flow chart" image description:

Inputs Up To and Including 400 MBH (120 kW)

- Air Tight Structure Complies with 8.2.1

- Appliances with Draft Control – Table 8.1

- Appliances without Draft Control – Table 8.2

- Both Types of Appliances. The Greater of: Table 8.1 for appliances with Draft Control. Table 8.2 for all Appliances.

- Loose Structure Does Not Comply with 8.2.1

- Appliances with Draft Control – Table 8.3

- Appliances without Draft Control – Table 8.4

- Both Types of Appliances with Draft Control. Table 8.4 for all Appliances

- Appliances are Located Within An Enclosure - Clause 8.2.6

Inputs over 400 MBH (120 kW)

- Appliances with Draft Control – Clause 8.4.2

- Appliances Without Draft Control – Clause 8.4.3

- Both Types of Appliances Clause 8.4.4

- Ventilation Duct Sizing Clause 8.4.1 [Return to Figure 8]