Competency D1: Install Sewage Treatment Systems and Components

Learning Task 2

Describe Municipal Sewage Disposal Systems and Sewage Treatment Plants

Learning Objectives

After completing this learning task, you will be able to:

- Describe the objective of a municipal sewage disposal system

- Identify the components found in a sewage treatment plant

- State the goals of municipal waste treatment

The principal objective of municipal wastewater treatment is generally to allow human and industrial effluents to be disposed of without danger to human health or unacceptable damage to the natural environment. The Public Health Act, Environmental Management Act, and Municipal Wastewater Regulation establish the criteria that local government must adhere to the interests of promoting and protecting the health and well-being of the public through the treatment and safe disposal of sewage.

Simply stated, a municipal sewage treatment plant does for a town or city what a private sewerage system does for a single-family residence. The differences are mainly:

- the scale at which the process occurs

- the size and complexity of the components

- the level of treatment achieved

- the chemistry and quality control used

- the end destination of the treated effluent

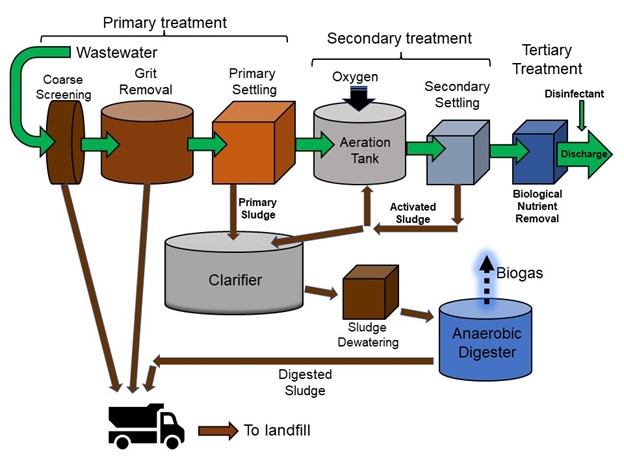

In a municipal treatment system, raw sewage from homes and businesses travels through a system of underground mains to a processing plant which is usually located near a natural body of water, typically a lake, river, or the ocean. Unlike a residential system, discharging treated effluent into the ground on such a large scale is not an achievable goal due to the sheer volume of waste involved. Consequently, the mechanical, chemical, and biological processes involved demand a high degree of monitoring and adjustments according to variations in the composition of the sewage entering the plant. The following are the four major processes, and a short description of each, that occur within most sewage treatment plants. Note that these processes may differ in their use or order of occurrence between plants. The four major processes are:

- Primary treatment

- Secondary treatment

- Tertiary treatment

- Sludge treatment

Primary Wastewater Treatment

Primary treatment removes solids like silt and plastics, which could cause blockage and damage of valves, pumps, channels, orifices, and other components of the system. The wastewater is first taken into a settling tank, also referred to as a grit removal unit, after which it goes through screening to remove large organic material. Once settled, these materials are held back while the remaining liquid is moved through to the more rigorous secondary phase of wastewater treatment. These large settling tanks are also often equipped with mechanical scrapers that continually drive collected sludge in the base of the tank to a hopper which pumps it to sludge treatment facilities. Non-biodegradables such as plastics are separated and transported to sanitary landfills.

Secondary Wastewater Treatment

Following primary treatment, the organic waste is usually broken down through biological processes. This entails the propagation of cultures and other micro-organisms that continually multiply under the right conditions and feed on organic waste, while also helping in the breaking down of some chemicals. For instance, when ammonia is oxidized, it is converted into nitrogen compounds like nitrate. Inorganic waste can, to a small degree, be treated biologically but for the most part, it will need chemical treatment. If the secondary stage is done properly, the outcome will be treated sewage that has very little toxicity.

The growth of the microbial population needed for secondary treatment is provided by the nutrients contained in the raw sewage. As well, the right temperature, pH, and dissolved oxygen must also be in place for the environment to be optimum for the growth of bacteria. On average, the most ideal environment should be approximately 25–32° Celsius, 5.5–9.5 pH and 2 mg/L of dissolved oxygen.

Tertiary Treatment

Once sewage water has undergone secondary treatment, it is then passed on for a final filtration before it is discharged into a body of water. This tertiary treatment phase typically takes place in a clarifier or settling tank. The settling tank is similar to the one that is used for primary treatment except that it is usually followed by a polishing filter. At this stage, bacteria, viruses, and harmful parasites are also removed from the water, usually by chlorination, but in some cases also by ozonation and ultraviolet disinfection. Chlorine is more cost-effective than UV or ozone disinfection, but chlorine residual in even minute amounts can harm aquatic life, and so de-chlorination of the final product may be necessary before the treated water can be released to the environment.

Sludge Treatment

A sludge treatment plant receives solids recovered from screens, grit traps, surplus sludge, and settling tanks. In old treatment plants, the sludge is passed on to huge ponds where the water is allowed to evaporate slowly and thereby return to the water cycle. The solids that remain are then burned as bio-fuel, buried, or sold as fertilizer. Modern sludge treatment facilities dewater the sludge using filters before passing the sludge to digesters. Anaerobic bacteria flourish in these digesters under the right conditions and help break down the sludge. Methane is produced as one of the main by-products of this process. This methane can be captured and used as fuel to generate electricity for use on the site. The waste sludge is then transferred to sanitary landfills.

Self-Test 3

Self-Test 3

Media Attributions

- Figure 25. “Municipal wastewater treatment flowchart” by Camosun College is licensed under a CC BY-NC-SA licence.