Competency E2: Coordinate Cross Trade Activities

Learning Task 4

Interpret Sections of the Canadian Electrical Code

As explained in previous learning tasks, apprentices and journeypersons in the piping trades will sometimes be expected to perform work that requires a base knowledge of electricity and its applications. The material in this learning task will focus on limited sections of the Canadian Electrical Code (CEC) as well as information in the BC Electrical Safety Regulation. This is information that may be needed for the limited electrical work a piping tradesperson may encounter. It is not intended to be an in-depth study of the CEC nor is it expected to replace the information usually covered in a face-to-face learning environment; rather, it is meant to help the tradesperson find pertinent information and apply it correctly. This learning task will concentrate on topics found in select sections of the CEC as well as information from the BC Electrical Safety Regulation.

Canadian Electrical Code (CEC)

As stated in the BC Electrical Regulation to follow, British Columbia has adopted the latest version of the CSA 22.1 Canadian Electrical Code, Part 1 “Safety Standard for Electrical Installations” as the relevant code for electrical work in the province. In addition to the usual documentation regarding history, acknowledgements, preface, scope and other content that is particular to most codes, the CEC is comprised of 86 sections (all even numbered for future insertions of sections), tables, diagrams, appendices A through M, and an index. Our focus will be on Sections 0, 2, 4, 8, 10 and 12, along with appendices B and D. Again, we will not attempt to cover all the information from these sections; moreover, we will touch on some of the key points within them in the hopes that the learner will have a better idea of how to use the code to find relevant information.

Section 0 – Object, Scope, and Definitions

Object – The stated objective of the CEC is “to establish safety standards for the installation and maintenance of electrical equipment. In its preparation, consideration has been given to the prevention of shock and fire hazards, as well as proper maintenance and operation.” It goes on to explain how these goals will be achieved and allows for alternatives to the requirements found within the Code. As well, it states “This Code is not intended as a design specification nor as an instruction manual for untrained persons.” The Code doesn’t specify how to perform a task, rather it specifies the minimum acceptable outcomes.

Scope – In its statement of “scope” the Code states “This Code applies to all electrical work and electrical equipment operating or intending to operate at all voltages in electrical installations for buildings, structures, and premises, including factory-built relocatable and non-relocatable structures, and self-propelled marine vessels stationary for periods exceeding five months and connected to a shore supply of electricity continuously or from time to time, with the following exceptions…..” which lists, in abbreviated form, aircraft, railways and their signaling systems, and ships that are regulated under Transport Canada. In short, with few exceptions, most electrical installations in Canada will fall under the rules the CEC.

Definitions

The Code defines terms that may differ from those found in a dictionary, in which case the Code definitions should be used. A dictionary meaning should be used for terms not listed in the Code definitions. The following are some of the Code terms that may apply to those working with electricity in the piping trades. Where definitions are accompanied by lengthy descriptions, we will endeavor to summarize the intent, in the quest for being as abbreviated as possible. The Code definitions and wording will appear in italics, with explanation appearing in normal font.

Approved (as applied to electrical equipment) – means equipment that has been certified by a certification organization accredited by the Standards Council of Canada in accordance with the requirements of

- a) CSA Group Standards

- b) other standards that have been developed….

In Canada, CSA is the predominant certification agency for electrical equipment. Although there are other certification agencies, if the CSA mark or logo is not on a piece of electrical equipment, it should be investigated as to being legally able to be installed.

AWG – the American (or Brown and Sharpe) Wire Gauge as applied to non-ferrous conductors and non-ferrous sheet metal.

The AWG scale ranges from AWG 0000 (known as “four ought” or “4/0”) which is large in diameter and can carry approximately 400 amps as a single copper conductor, to AWG 40 which is very small in diameter and can only carry approximately 0.0137 amps.

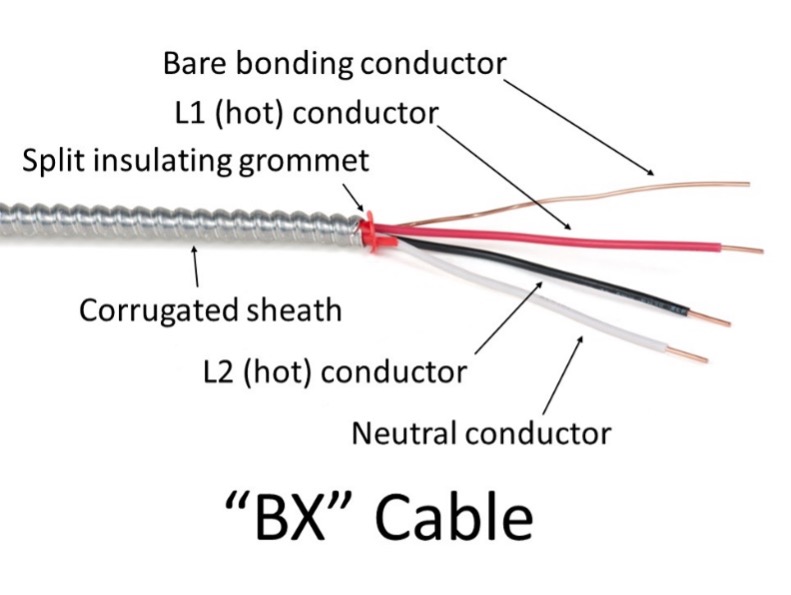

Bonding – a low impedance path obtained by permanently joining all non-current-carrying metal parts to ensure electrical continuity and having the capacity to conduct safely any current likely to be imposed on it.

Bonding electrical equipment together, back to a ground connection, ensures that, if a metal component of a circuit were to become energized (“hot”) the current would race back through the bonding conductors to ground and, with no appreciable resistance in the circuit, the resulting excessive amperage would cause the overcurrent protection to deaden the circuit. Bonding conductors are usually bare or covered with green insulation if in a flexible cord. An example of the bonding conductor in a BX cable is shown below.

Cellular floor – an assembly of cellular metal or cellular concrete floor members, consisting of units with hollow spaces (cells) suitable for use as raceways and, in some cases, non-cellular units.

Many buildings have areas dedicated to their data equipment. Computer mainframes are located on top of the raised floor and all the cabling is laid below, accessible via removable floor tiles, as seen below.

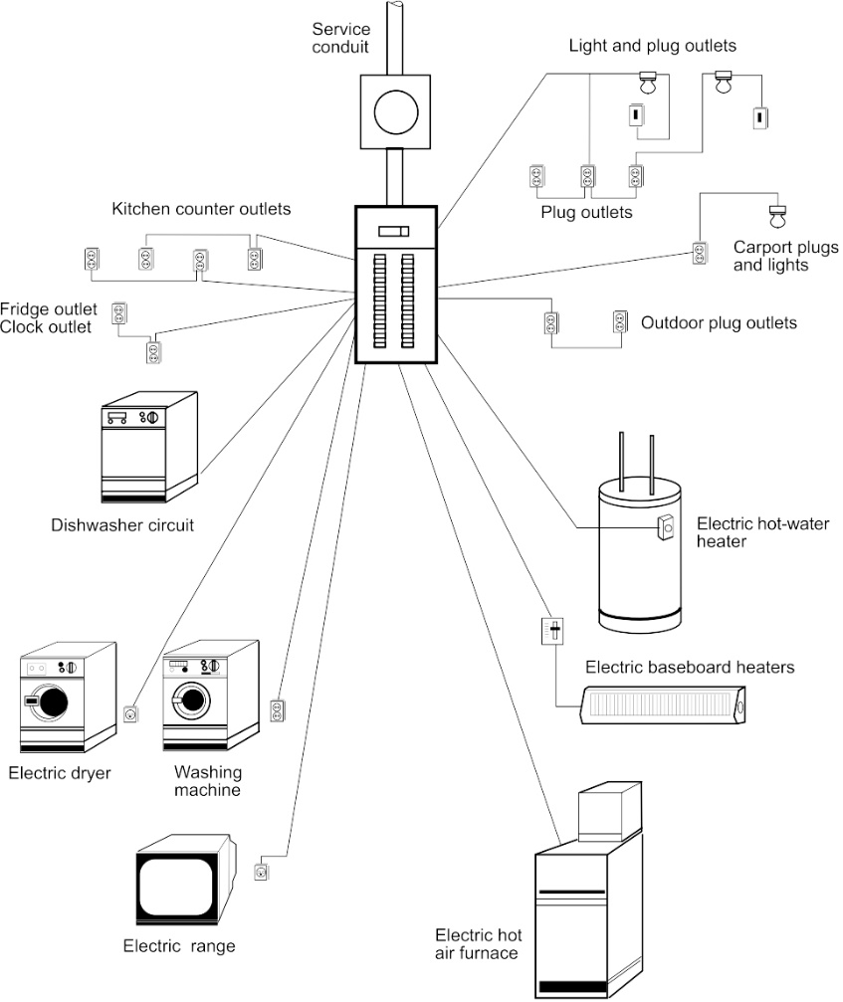

Branch circuit – that portion of a wiring installation between the final overcurrent device protecting the circuit and the outlet(s).

A branch circuit in a house starts at the connection to the circuit breaker in the main distribution panel, progresses through conductors, switches and loads, and ends at the ground bar connection in the panel.

Extra-low-voltage power circuit – a circuit, such as a valve operator and similar circuits, that is neither a remote control circuit nor a signal circuit, but that operates at no more than 30 V and is supplied from a transformer or other device restricted in its output to 1000 VA, but in which the current is not limited in accordance with the requirements for a Class 2 circuit.

Section 16 of the Code deals with circuits that have limitations of voltage and/or amperage imposed upon them. Otherwise, the voltage and current present in a circuit is as according to the equipment being served.

Conduit – a raceway of circular cross-section, other than electrical metallic tubing, into which it is intended that conductors be drawn.

The Code lists many varieties of conduit under this heading. For instance, rigid metal conduit is Schedule 40 steel, which can be threaded and may also be galvanized.

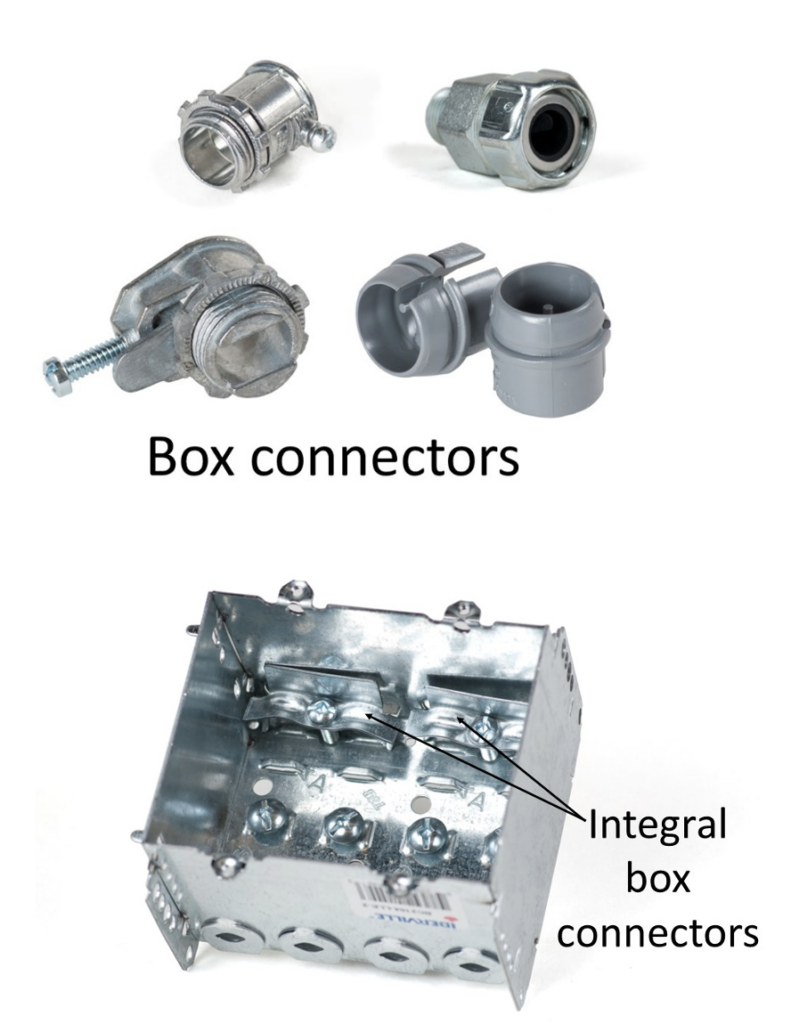

Connector (box connector) – a device for securing a cable, via its sheath or armour, where it enters an enclosure such as an outlet box.

A box connector grips the sheath or armour so that the cable cannot be pulled out of the box. Some boxes have integral box connectors.

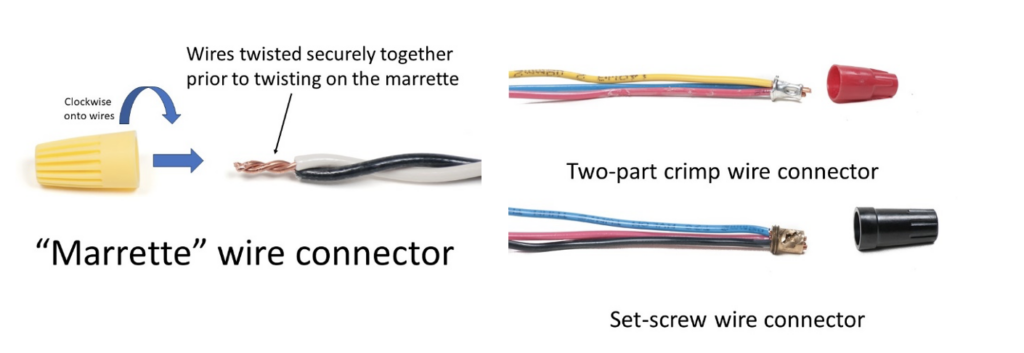

Connector (wire connector) – a device that connects two or more conductors together or one or more conductors to a terminal point for the purpose of connecting electrical circuits.

The most common wire connector is often referred to as a “marrette” in reference to the company that likely pioneered the fitting. It is also referred to as a “twist-on” type of connector. Two other types of wire connectors are also shown below.

Duty – a requirement of service that demands the degree of regularity of the load.

This term is usually associated with motors and has five categories listed. For example, “short-time duty” is defined as “a requirement of service that demands operation at a substantially constant load for a short and definitely specified time”. In other words, the load of the motor occurs periodically, remains constant for short time and then remains idle for longer time, giving it time to cool.

Electrical metallic tubing – a raceway of metal having circular cross-section into which it is intended that conductors be drawn and that has a wall thinner than that of rigid metal conduit and an outside diameter sufficiently different from that of rigid conduit to render it impracticable for anyone to thread it with standard pipe thread.

Electrical metallic tubing (EMT) is most often used where wiring must be exposed and surface mounted. It is held together with set-screw fittings.

Identified – when applied to a conductor, signifies that the conductor has:

- a white or grey covering, or

- a raised longitudinal ridge(s) on the surface of the extruded covering on certain flexible cords, either of which indicates that the conductor is a grounded conductor or a neutral.

The Code often references “the identified conductor” rather than “the neutral” in a circuit as the conductor that is grounded. A power conductor, especially one in a raceway with other conductors, can have any colour insulation on it and should be assumed to be a hot wire; the assumption when seeing a white insulated wire is that it is a neutral or common wire and carries no electrical potential, and can be safely handled. Always check for voltage before making any such assumptions.

Location – The Code defines six locations, which are damp, dry, hazardous, ordinary, outdoor, and wet. These have relevance when determining the type of conductors, for instance, that are contemplated to be used in a circuit. For example, a dry location is “a location not normally subject to dampness, but that may include a location subject to temporary dampness as in the case of a building under construction, provided that ventilation is adequate to prevent an accumulation of moisture”. A house may be wired only after the roofing is installed and the building’s doors and windows are in place (“lockup stage”), to prevent it from being considered a wet location, for which the wiring normally used would not be approved.

Low-voltage release – a device that operates on the reduction or failure of voltage to cause interruption of power to the main circuit, but not to prevent its re-establishment on the return of voltage to a safe operating value.

Two simple examples of low-voltage release (LVR) are a simple lighting circuit and a television. If power goes out for any reason, those two loads are dead. When power comes back on, so do the two loads in which case voltage is “released” to the loads. A microwave oven is an example of a low voltage protected (LVP) device. When power comes back on, it beeps and will need to be reset before it can operate. It may be unsafe if it operates as a LVR device. Low-voltage release (LVR) is very useful for circuits where re-energization after a brief or temporary loss of power is safe and desirable.

Overcurrent device – any device capable of automatically opening an electric circuit, under both predetermined overload and short-circuit conditions, either by fusing of metal or by electromechanical means.

Fuses are examples of “fusing of metal” (meaning melting) and circuit breakers are “electromechanical devices”. Both will cause an open connection which interrupts power to the circuit. Some switches use a bi-metal element that reacts to excessive heat caused by overloading a motor, cur power to the motor, and will either reset automatically once cooled sufficiently or will need to be manually reset.

Raceway – any channel designed for holding wires, cables, or busbars, and, unless otherwise qualified in the Rules of this Code, the term includes conduit (rigid and flexible, metal and non-metallic), electrical metallic and non-metallic tubing, underfloor raceways, cellular floors, surface raceways, wireways, cable trays, busways, and auxiliary gutters. This definition is self-explanatory.

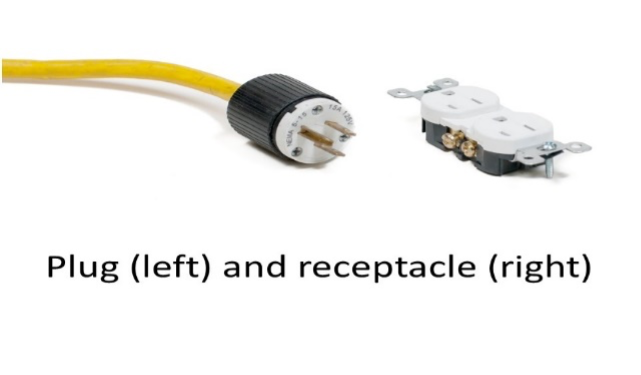

Receptacle – one or more groups of female contacts, each group arranged in a configuration, all groups mounted on the same yoke and in the same housing, installed at an outlet and intended for the connection of one or more attachment plugs of a mating configuration.

In electric-speak there is no such thing as a “wall plug”, as a plug is the male counterpart to the receptacle.

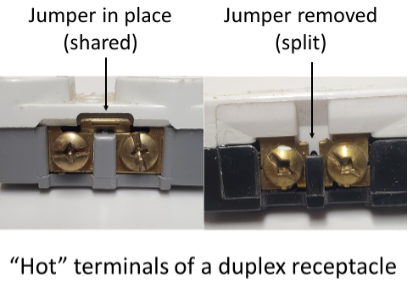

A shared receptacle has one hot wire from a circuit connected to one of the brass terminals which powers both sides of the receptacle via the jumper connection. A split receptacle is used where there are two circuits sharing the same receptacle or yoke, such as for kitchen counter receptacles, or where there is a 120 V constant-power outlet and a switched outlet, such as for a lamp in a living room. The tab connecting the hot terminals is snapped off and a hot wire from two separate circuits connects to the terminals.

Voltage – there are three voltage designations as applies to the CEC and electricians, and they are:

- Extra-low voltage – any voltage not exceeding 30 V

- Low voltage – any voltage exceeding 30 V but not exceeding 750 V, and

- High voltage – any voltage exceeding 750 V

Now complete Self-Test 3 and check your answers.

Now complete Self-Test 3 and check your answers.

Self-Test 3

Self-Test 3

Media Attributions

- Figure 17. “BX Cable” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 18. “Cellular floor tile removed for access to wires and cables” by Universidade Federal do Ceará on Flickr is licensed under a CC BY-NC 2.0 licence.

- Figure 19. “Common branch circuits in a house” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 20. “Box with integral box connectors” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 21. “Wire connectors” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 22. “Electrical metallic tubing (EMT)” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 23. “Plug (left) and receptacle (right)” ©SkilledTradesBC, Province of British Columbia. These resources are not designed for rework, reuse, remixing, and/or redistribution; they are to be used solely for the purposes of instruction.

- Figure 24. “Hot terminals of a duplex receptacle” by Camosun College is licensed under a CC BY-NC-SA licence.