Competency F1: Test and Service Sanitary and Storm Drainage Systems

Learning Task 4

Describe Maintenance Procedures for Manholes, Catch Basins, and Piping for Sewers

Inspection

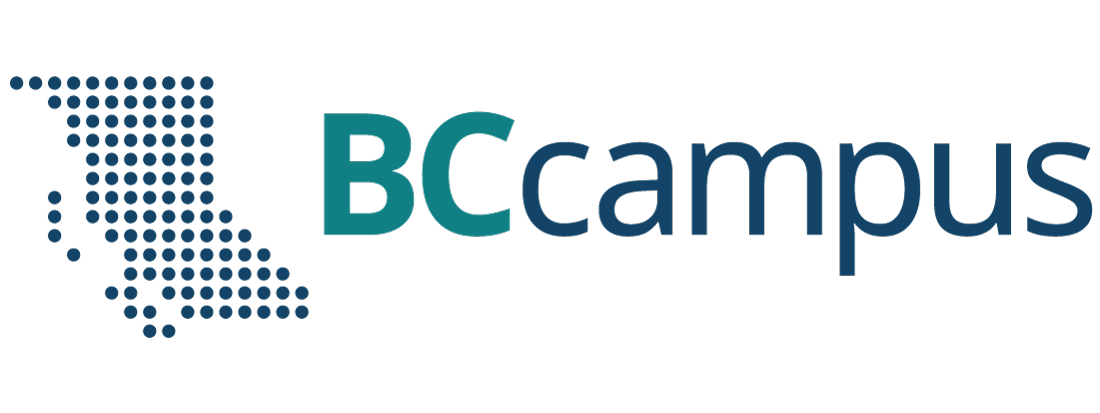

A manhole is a composite or concrete chamber installed at specific intervals along sewer lines, that allow access to the pipes entering and exiting them (Figure 12). Sometimes referred to as inspection chambers, manholes allow inspection, cleaning, and maintenance of sewers without needing to dig them up. They are normally installed at every bend, junction, change of gradient or change of diameter of the sewer. The sewer line between any two manholes is normally laid straight with consistent gradient to minimize the chance of blockages forming at any point between manholes.

The NPC code 2.4.7.3. ensures that manholes area accessible by requiring the following:

- A manhole, including the cover, shall be designed to support all loads imposed upon it.

- A manhole shall be provided with

- a cover that provides an airtight seal if located within a building

- a rigid ladder of a corrosion-resistant material where the depth exceeds 1m, and

- a vent to the exterior if the manhole is located within a building

- A manhole shall have a minimum horizontal dimension of 1m, except that the top 1.5m may be tapered from 1m down to a minimum of 600 mm at the top.

- A manhole in a sanitary drainage system shall be channeled to direct the flow of effluent.

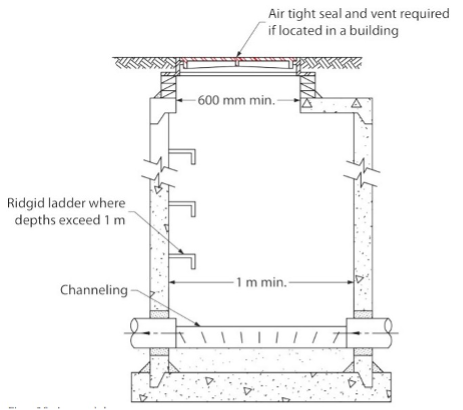

A catch basin or storm drain is a curbside drain with the sole function of collecting rainwater from our properties and streets and transporting it to local waterways through a system of underground piping, culverts and/or drainage ditches. Storm drains can also be found in parking lots and serve the same purpose. (Figure 13) The catch basin grate can be lifted for access and inspection.

Piping for sewers is the pipe exiting a structure and is connected to a building drain 1 m outside a wall of a building and that leads to a public sewer or private sewage disposal system. Typically, this piping is installed, maintained, repaired, and replaced by the city or with their permission.

Schedules

Typical maintenance schedules call for an annual inspection of manholes, catch basins and the sewer piping although these checks may be required at more regular intervals if the system collects excess amounts of dirt and debris. The best time of year to clean out a catch basin is late summer or early fall. This ensures the unit will function properly and continue to direct storm and sewer water away from the building during the season’s highest rainfall.

Testing

Smoke

A smoke test can be performed on sewer pipes by introducing smoke into the piping and confirming none is escaping through smalls leaks. Smoke testing can be helpful in identifying leaks in spots that are hard to see or when the weather requires its use. During smoke testing, field crews blow air and smoke into the sanitary sewer system and monitor where smoke escapes. If smoke permeates up through the ground, it indicates a break in the sewer line. (Figure 14)

Cameras

A camera can be used to inspect catch basins, manholes, and sewer pipe. A high-resolution sewer pipe camera is fastened to the end of a flexible rod (Figure 15). A professional then inserts the rod, along with the camera into the pipes to check for problems. Using a flexible rod permits for more improved mobility inside pipes and sewer lines.

Specifications, Codes, and Regulations

The BC Plumbing Code is intended to ensure the quality and functionality of plumbing systems and to protect the health of the occupants of the premises where a plumbing system is to be installed, as well as the health of the public in general. As a result of this intent, drainage and venting pipes are required by Code to be pressure tested after installation of each phase of the project.

The term authority having jurisdiction, commonly referred to as AHJ, covers a variety of regulating organizations. In our trade, the most common application is in reference to the building official responsible for Plumbing Code and regulation enforcement. For the building official, the limits may be the Building and Plumbing Codes adopted by the jurisdiction. Quite often, local AHJ may require a DWV installation to meet by-laws or regulations that address local conditions before they will give approval. Some examples of local regulations could include using piping materials that are suitable for local soil conditions, or the depth that piping must be buried to prevent freezing.

Tools and Equipment

Snakes

Snakes can be an easy, effective way to remove clogs in sewer pipes and maintain efficient drainage. Depending on the size of the clog and pipe, maintenance staff can choose from multiple options including hand augers, closet augers, and powered augers. Snakes also have several detachable heads that can be selected based on the job at hand. These heads include ones for cutting through grease, hair, and even hardened mud. (Figure 16).

Jetters

A hydro jetter can clean more efficiently than snaking alone (Figure 17). Snaking can remove clogs, but some particles are often left behind. Hydro jetting is environmentally friendly, and no punitive chemicals are used just high pressure water.

Cameras

Video inspection equipment uses a remote video camera to inspect underground sewers and drains. Proper maintenance will sometimes require visual confirmation that piping and components are in good condition. A video can be taken and saved to a USB drive to document the procedure and findings of the inspection.

Vacuum Trucks

Vacuum trucks may be required when inspecting a manhole or catch basin. (Figure 18) They are equipped with a pump and a tank for removal of fluid in the manhole or catch basin. Vacuum trucks can pump out contents and allow for access to a pump, inlet and outlet piping. Once a manhole or basin is emptied, service personnel can climb in and perform maintenance tasks such as clearing a pump, baffle, or filter of any excess debris. This is also an opportunity to check for damage to a pump or the piping.

Isolation

Maintenance for a manhole, catch basin, or sewer piping may require the isolation of system components. A drainage system has challenges when attempting to isolate its parts. Mainly, it is difficult to stop occupants from using their fixtures that are connected to a sanitary sewer. Steps can be taken to attempt to lessen their use by way of signs in large buildings and communication from building managers. Maintenance for storm systems is best done on dry days to eliminate rainwater from entering the system while performing maintenance tasks.

Manholes and catch basins can be isolated at the inlets and outlets, however, service personnel must take care when removing things like test plugs because there could be waste or rainwater building behind the plug.

Return to Service

In accordance with the NPC, any design, installation, extension, alteration, renewal, or repair of a plumbing system must satisfy the testing requirements. Before returning a system to service you must ensure that it is properly tested. When returning a system to service it is recommended to notify the users of the system that maintenance is complete.

Documentation

The procedure and requirements for a certificate of approval or passed inspection can vary widely from jurisdiction to jurisdiction and with the type of structure. Some projects may require certification from the installer that the plumbing system functions according to the approved design.

Now complete Self-Test 4 and check your answers.

Now complete Self-Test 4 and check your answers.

Self-Test 4

Self-Test 4

Media Attributions

- Figure 12. “Sanitary Manhole” by ITA is licensed under a CC BY-NC-SA licence.

- Figure 13. “Street level catch basin” from Edenflo Pump Truck Services is used for educational purposes under the basis of fair dealing.

- Figure 14. “Smoke testing a sewer” by TeWeBs is licensed under a CC BY-SA 4.0 licence.

- Figure 15. “Camera Inspection” from Dry-Rite Home Solution is used for educational purposes under the basis of fair dealing.

- Figure 16. “Drain snake attachable heads” from Populo on Amazon is used for educational purposes under the basis of fair dealing

- Figure 17. “Hydro Jetter” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.

- Figure 18. “Sewage Vacuum Truck” by Anneli Salo is licensed under a CC BY-SA 3.0 licence.