Competency F1: Test and Service Sanitary and Storm Drainage Systems

Learning Task 1

Describe the Maintenance and Repair of Drainage, Waste, and Venting (DWV) Systems

After a drainage, waste, venting system has been installed, there is a set of processes and practices followed to ensure the continuous and efficient operation of the piping and its components. Even a little water damage can be costly to repair and cause health concerns if mould and mildew begin to grow. A leak in the sanitary system can expose occupants to harmful substances and gases.

To avoid disasters, such as a sump pump failure or a kitchen sink overflow, regular maintenance should be performed by home occupants, building managers, and service plumbers. All maintenance should be done in accordance with the manufacturer’s guidelines.

Pumps

Pumps found in our DWV and storm systems can include:

- Sump Pumps

- Sewage Ejector Pumps

If a building is below the water table, groundwater will need to be contained and discharged away from its foundation. That is the job of a sump pump. Like any other appliance or fixture, a sump pump requires regular maintenance to keep it functioning properly.

A sump pump system includes a motor, a pump, float sensors, and discharge piping. The NPC requires that the discharge piping has a union, a backwater valve, and an isolation valve.

Unless a home has been subject to flooding, an annual inspection is the usual recommendation for sump pump maintenance. Larger commercial buildings may have more regular checks. The pump’s pit should be inspected, and any excess debris removed to avoid blockages. If you are inspecting a very large pit, you may need it to be vacuumed before a thorough check can be performed. Make sure to disconnect the pumps power supply before draining the pit so that the pump does not run dry. Once the pit is cleared perform the following check list:

- Check the pump’s screen for dirt buildup

- Ensure the float or floats can move freely

- Check the piping for damage

- Check the pump’s backup power supply (battery)

After inspection of the pit and pump, do a trial run. Fill the pit with water, energize the pump, and make sure it is discharging up and away from the building. Watch for any leaks in the discharge piping. Between the pump and check valve, you will notice water escaping. That is the weeping hole and is necessary to help vent the discharge pipe to avoid air lock. Except for the pipe’s weeping hole, no other water should escape.

Sewage ejector pumps are essentially the same as sump pumps, but discharge sewage rather than storm and ground water. If a building’s lowest point is below that of the city sewer or septic tank, a sewage ejector pump must be used. For example, if a homeowner decides to add a bathroom to their basement, often a sewage ejector pump will be required to pump waste up and out to the city sewer. Waste is drained to a sump and pumped out as needed.

In commercial buildings, there can be multiple sumps and sewage ejectors that require regular inspection and maintenance.

Sumps are considered a confined space and should not be entered unless you are properly trained and ticketed.

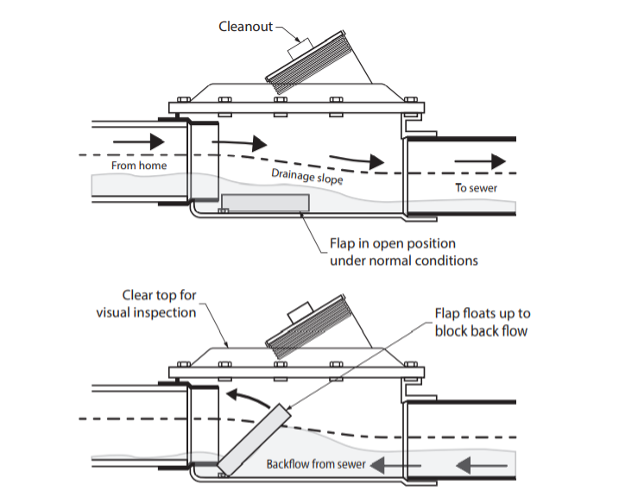

Backwater Valves

Backwater valves are a one-way flow control valve installed in a drainage system. Under normal conditions it allows the wastewater to drain out of the system, but if a reversal of flow should occur, the valve is forced closed and protects the interior of the building from sewage backup.

Backwater valves (Figure 2) are required to protect fixtures and drainage openings that are installed below grade, such as in a basement, where the possibility exists for the municipal sewage or storm water systems to become overloaded and force wastewater back through your drains. Backwater valves are also required on any subsoil drainage pipe that connects into the sanitary drain, to protect it from sewage backups.

To maintain a backwater valve, the following checks can be performed:

- Locate your backwater valve and remove the plug or panel.

- Shine the flashlight around the area and look for debris. Debris stuck in the gate can cause the sewer backwater valve to stop working.

- Clean the area. Flush the valve with a bucket of water to clear debris from the gate area. If that doesn’t work, scrub the area to remove it.

- Once clean, move the gate back and forth to make sure it moves without any problems. If it’s stiff or you see rust, oil it a little bit.

- Check the O-ring on the backwater valve. If it’s cracked or damaged, replace it.

- Replace the plug or panel on top of the valve.

Baffles, Filters, and Strainer Baskets

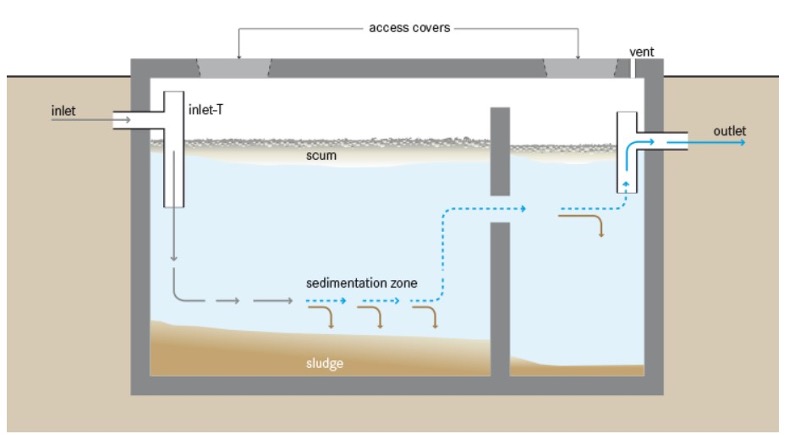

Baffles, filters, and strainers are used to help separate solids from liquid waste. As the solids collect, the baffles, filters, and strainers can become clogged and ineffective. Therefore, they require cleaning or replacement to maintain effectiveness. Baffles and filters are commonly found in septic systems. (Figure 3) Baffles are inside the tank, while filters are on the inlet and outlet piping, but the terms are sometimes used interchangeably.

The baffles and filters can be inspected visually at the accesses covers and cleaned, cleared, or changed when necessary. An inlet filter can become clogged, for example, by too much toilet paper being flushed. A baffle scraper or rod can be used to clear away large solids and restore draining.

Strainer baskets are also used in the DWV system to separate solids from liquid and reduce the load travelling down the drain. Strainer baskets such as the ones found in kitchen sinks must be cleared manually (Figure 4).

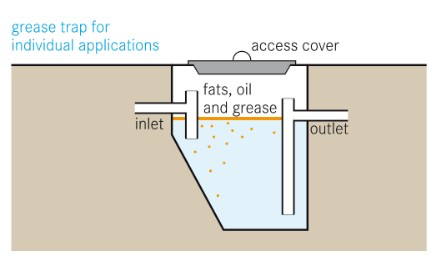

Interceptors

Grease and organic interceptors are drainage equipment located between kitchen drain lines and sanitary sewer lines. Grease interceptors capture the fats, oil, and grease (FOG) flowing down kitchen drains and stop them from flowing to the sewer. Organic interceptors capture food waste. An organic interceptor is permitted to be installed upstream of a grease interceptor and both require maintenance.

An interceptor (Figure 5) will have an access cover that allows for the cleaning. Large solids are pulled or vacuumed out of the trap, the lid and the sides scraped down and debris vacuumed out. The lids, trap sides, and parts are then cleaned with soap and room-temperature water. Proper disposal is necessary after removing grease from the interceptor and service personnel must follow the jurisdiction’s guidelines when doing so.

Drain Cleaning Equipment

Video inspection equipment uses a remote video camera to inspect underground sewers and drains. These machines are not meant to clear stoppages, so the drain is typically cleared first using a cleaning auger. They provide an excellent way to detect and locate obstructions or damage that impedes or stops the flow of drainage lines. Video inspections can detect such common problems as:

- Root-bound drainage lines

- Pipe collapse and cracks

- Running inline traps

- Negative grade sloping

- Pipe sagging

- Offset joints

- Sludge build up

The video camera equipped with LED lighting is fed down the drain or sewer line from a reel on the surface to a recording monitor. A service technician receives the live picture and views it on a monitor as the video records to a flash drive or DVD archive for future reference.

Pipe Locators

On some models of video inspection equipment, the camera is equipped with a radio transmitter. The camera/transmitter assembly sends a signal to a receiver on the ground surface indicating the camera location and depth of burial. This information can be used if the line must be excavated and repaired.

Drain Augers

A drain auger is a long, flexible metal cable that rotates in a circular motion and is powered by hand or electrically. On some models the attachment that goes on the end can be changed to meet specific job requirements. The drain auger is inserted and rotated into a drain until it reaches the obstruction. The auger then displaces, retrieves or reduces the obstruction so the drain can flow freely.

There are several different types of drain augers for home and commercial use:

- Hand auger

- Closet auger

- Power drum auger for small-diameter piping

- Power drum auger for large-diameter piping

Hand Auger

The hand auger (Figure 6) uses a drum to contain the cable and keep it from tangling and kinking. These tools are useful for clearing small diameter sink and bathtub drains (up to 2″ NPS) when the obstruction has yet to solidify. Do not attempt to send this auger through toilet bowls, because the exposed wire cable might damage the porcelain finish. Also, due to the large bowl passageway and the cable’s small diameter, the cable can be become tangled when rotated. Some hand augers can be attached to an electric drill, giving it more power to force it through the clog.

Closet Auger

The closet auger, named after the “water closet,” feeds a relatively short cable through a hook shaped length of metal tubing. The hook shape makes it easier to feed the cable into the toilet. A plastic boot on the end of the cable protects the finish of the visible porcelain. Since most toilet clogs occur in the integral trap, the short cable is sufficient to break up or retrieve most clogs.

Power Drum Augers (Small-Diameter Piping)

This power auger consists of a drum containing a length of cable (15 m/50′ of ¼” or 5/16″; or 10 m/35′ of 3/8″) that is generally mounted on the end of a variable-speed electric drill. This hand-held drain cleaner can clear clogs in lines from 32 mm to 75 mm (1¼”–3″) in diameter in awkward and tight spaces. The motor also has a quick-reversing switch to help release the cable should it get caught in a drain line. The rotation of the drill is used to unspool and drive the cable down a pipe. The cable is gripped by a chuck that must be loosened by hand for the cable to be loosened and manually fed into the drain and must again be hand-tightened to lock the cable in place. When the cable reaches the clog, the tip begins digging into and loosening the material. This is where an electric power drum auger offers many benefits over a manual version. Using a hand auger, you are limited to the power you can generate and maintain with your hands alone. With a power auger, you can slowly ease up the pressure you are applying to a clogged drain in order to be more effective at getting rid of the obstruction.

Power Drum Augers (Large-Diameter Piping)

This power tool consists of a cable 30 m (100′) or sometimes 15 m (50′) long wrapped inside a metal drum or cage-like spool, which is turned by a reversible electric motor. These tools are incredibly powerful, using low internal gear ratios to move slowly but with enough force to break apart or cut tough material. These machines are too heavy for one person to carry, so they are typically equipped with a frame with two wheels, allowing it to be rolled around like a dolly. To use this type of tool, position the auger a few feet away from the cleanout and plug its power cord into a nearby grounded electrical outlet. Most augers have a foot pedal that allows the motor to be controlled hands-free; set this down in a convenient location. (Figure 7)

Pull out the cable and feed it into the pipe a few feet, then press the pedal to start spinning the cable (and cutter head) in the normal (clockwise) rotation. While the auger is spinning, pull the cable off the spool and feed it into the drain a foot or so at a time. In addition to powering the cutting action, the rotation helps the cable work its way through bends in the drain pipe. If the cable meets resistance, it could be an offset or obstruction. In either case, don’t try to force the cable forward. Back off the cutter head by retracting the cable a bit, then feed it in again.

When the cutter encounters an obstruction, it may grab the material and stop turning while the cable keeps spinning. The cable is a tightly wound torsion spring, so you can let it wind up for a few rotations but going too far can break it. Let the energy build up a little bit, then pull the cable back to free the cutter blade; the cable will instantly spin back to its normal position. If the cutter gets stuck and you can’t get the cable unwound, stop the auger rotation, hit the reverse switch on the motor, and rotate the auger backward. Then pull the cutter free before resuming in the clockwise rotation. Once the cable returns to the normal position, start feeding it in again.

Repeat the process until the drain is clear. Often, it’s necessary to pull the cable all the way back out to check the cutter head for roots and other debris. Advantages of electric drain cleaners include the ability to clean long sections of sewer drain and the ability to remove solid objects such as tree roots. Machines using flexible attachments can easily negotiate multiple 90-degree bends while maintaining their effectiveness and without damaging the pipe.

Water Jetters

This is a method of cleaning or unclogging drains and sewers using high-pressure water to remove debris. High-pressure water jetters usually operate with water pressures up to 28 000 kPa (4000 psig) with flow rates of 9 to 113 litres (2 to 25 gal.) of water per minute. The pressure of the water jet propels a highly flexible hose through lines measuring 32 to 100 mm (1¼” to 4″), blasting through sludge, soap and grease blockages. As you pull the hose back, it power scrubs the line, flushing debris away and restoring drain lines to their free-flowing capacity. Because of the introduction of water into an already plugged line, the drainage pipe is ideally cleaned from the downstream end of the pipe, and the hose propels itself upstream.

When it is impossible to clean from the lower end of the pipe, the pipe must be water jetted several times to remove all the debris. Water jetters can be truck-mounted and may carry up to 6800 litres (1500 gal.) of water for large sewer cleaning jobs, or they can be mounted on a trailer and pulled by a large van or small truck. Smaller water jetters can be mounted on a cart for residential and light commercial applications. When using this type of tool for a residential job, be aware of any cross-contamination issues. Consider the location of your source water: does it come from a tank in your truck or from a hose bib on the property?

Air Blasters

Air blaster drain cleaners use accelerated carbon dioxide, air or other gas to rupture the obstruction membrane. Accelerated gas creates a force on standing water that can dislodge clogs that accumulate close to drain openings but are too far away from the drain opening to be removed with a plunger. Unlike drain augers, air blasters do not pose any risk of scratching the surfaces of ceramic sinks, bathtubs and toilets. Disadvantages of air blaster drain cleaners include a limited cleaning range in pipes that do not contain standing water and, in general, ineffectiveness for unclogging blocked main sewer drains. Safety considerations for air blaster drain cleaners include a requirement to wear eye protection and, when using an air-burst cleaner that uses compressed gas cartridges, careful handling of unused cartridges

Steam Cleaning

Unlike air- and water-jet systems, steam cleaning is an entirely different process. The steam cleaner uses steam’s expansion to accelerate water droplets, at the boiling point, to a high velocity. The closer the steam cleaner’s nozzle is to the surface to be cleaned, the higher the temperature and velocity of the water/steam mixture, and the more rapid the cleaning action. The temperature of the water/steam mixture drops quickly as the distance between the nozzle and the surface to be cleaned increases. Consequently, for drain-cleaning applications, the nozzle should be held close to the inner surfaces to achieve the best results.

Shop Vacuum

Most shop vacuums have an output blower mode that should be powerful enough to clear small drain obstructions. Place the end of the vacuum hose firmly over the drain and seal the edges to maintain output pressure. Make sure any other drain openings are closed or tightly plugged. In blower mode, quickly turn the power on and off repeatedly until you dislodge the clog from the drain. Leaving the blower to run continuously for a long period of time can damage your pipes (or the vacuum, if its air flow is restricted)

Now complete Self-Test 1 and check your answers.

Now complete Self-Test 1 and check your answers.

Self-Test 1

Self-Test 1

Media Attribution

- Figure 1. “Basement Sump Pump” by State Farm on Flickr is licensed under a CC BY 2.0 licence.

- Figure 2. “Backwater Valve Operation” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.

- Figure 3. “Septic Tank Arrangement” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.

- Figure 4. “Kitchen sink strainer basket” by Stilfehler is under a CC BY-SA 3.0 licence.

- Figure 5. “Grease Interceptor” by eCompendium of sanitation systems and technologies is licensed under a CC BY 3.0 licence.

- Figure 6. “Drain Auger” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.

- Figure 7. “Power Drum Auger” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.