Competency F1: Test and Service Sanitary and Storm Drainage Systems

Learning Task 3

Describe the Testing of Manholes, Catch Basins, and Piping for Sewers

Manholes, catch basins, and piping for sewers are required by code to be tested using an acceptable test method and then pass an inspection. Improperly installed components could allow unsanitary conditions to occur inside a building and allow toxic gases to enter. If an alteration to the system occurs after the test and inspection, the piping system will have to be re-tested and inspected.

Types

Sensory

Before any water, air, or otherwise is used for testing, a plumber can do a visual inspection for any obvious signs where a leak could occur. All clamped joints should be inspected and checked for tightness. Glued joints will have signs of primer or glue to confirm they were properly connected. Catch basins or manholes may have visible cracks that can be repaired before adding water for testing. If older pipe is being tested, be sure to check for excessive external corrosion that can lead to cracking of the piping.

Hydrostatic

A hydrostatic or water test is the most common test used after installation. This is the recommended test in most plumbing codes, weather permitting. To test the sewer piping, the pipe must plugged at its most down steam end. Fill the system with water at the highest point, if available. Filling the system slowly should allow any air in the system to escape as the water rises in the pipe. All air entrapped in the system should be expelled prior to beginning the test. Failure to remove entrapped air may give faulty test results. As per the NPC, a 3m water column must be maintained for 15 minutes for a successful inspection.

To test catch basins or manholes, plug the inlets and outlets. Fill the basin or manhole with water. Ensure the water level remains constant verifying that there are no leaks.

Smoke and Air

When a system has been completely installed and some sections may be obscured from view, a smoke test may be required by engineers, architects, or plumbing codes to find leaks in the piping. A thick, penetrating smoke produced by one or more smoke machines is introduced into the bottom of the system through a suitable opening. As the smoke appears at the highest point, the opening is closed off and the introduction of smoke is continued until a pressure equal to 25 mm (1”) of water is built up and maintained for 15 minutes without the addition of more smoke. Under this pressure, smoke should not be visible at any point, connection, or fixture. Smoke testing can identify sections of the sanitary sewer system that have defects such as cracks, leaks or faulty connections that allow rainwater to enter the underground pipe network.

Two types of smoke are currently offered for smoke testing:

- smoke candles

- smoke fluids

To use a smoke candle, simply place one on the fresh air intake side of the blower. Once the candle has been ignited, the exiting smoke is drawn in with the fresh air and blown down into the system. This type of smoke is formed by a chemical reaction and has a high content of atmospheric moisture. It is very visible even at low concentrations and extremely effective at finding leaks.

A smoke fluid system involves injecting a smoke fluid (usually a petroleum-based product) into a heating chamber such as the engine exhaust muffler of a portable blower engine. The smoke is then exhausted into the fresh air intake side of the blower. Smoke fluids do not consistently provide the same quality of smoke because, as fluid is injected into the heating chamber, it immediately begins to cool the heating surface. The heating chamber will eventually reach a point where it is not hot enough to completely convert all the fluid to smoke, and it will then produce thin, wet smoke that is difficult to see. This can happen quickly, depending on the rate of fluid flow. Some manufacturers have taken steps to address this issue and now offer insulated heating chambers to help maintain necessary temperatures.

An air test may also be used when weather could cause standing water in a system to freeze or when testing piping above sensitive or expensive equipment. The system is filled using an air compressor

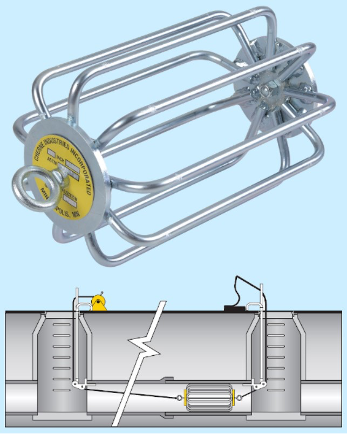

Mandrel

A mandrel test is the inspection inside underground pipes and sewer conduits. This happens after new construction or maintenance. This test is usually issued by the cities to test the public sewer lines. This test will show whether the pipe has bent under stress and pressure of the soil above.

The mandrel is cylindrical in shape and constructed with an odd number of evenly spaced arms or prongs, with a minimum 9 in number. (Figure 9) The minimum diameter of the circle scribed around the outside of the mandrel arms is equal to the allowable deflection.

The deflection test (Figure 9) is conducted by pulling the test device through a completed sewer run, from manhole to manhole. If the mandrel gets caught in the pipeline and cannot be pulled through the line in one straight pass, the line will fail inspection.

Equipment

Inflatable Test Balls

Inflatable test balls are blown up using a bicycle pump. Once placed in the opening to be plugged, use the pump to inflate the ball to its rated PSI. The PSI rating of the test ball will be imprinted on the test ball and should not be exceeded.

Test Plugs

Whether the test is by water, air or smoke, all openings in the test section must be sealed. Test plugs are often used in industry because they may be used repeatedly and are therefore cheaper to use than one-time-only test caps. Test plugs are available in several configurations, such as inflatable for use in a line cleanout or inflatable for use in a wye fitting.

Faults

When testing any part of the DWV system there are many faults that could be discovered. Once found these faults require repair or replacement and a retest shall be performed.

Cracks

If a manhole, catch basin, or sewer pipe has a crack or multiple cracks, it will not be able to hold water during a test. Once a crack is discovered repair will be in order.

Corrosion

Corrosion is caused by an electrochemical reaction between metal and another substance. When this happens, the metal in a pipe loses electrons. They are transferred from the metal to the other substance. As corrosion continues, the metal breaks down further and this causes rust, leaks, and clogs.

Oxygen is known to degrade metal through internal oxidation. Since water contains oxygen, it will cause pipes to rust over time. Corrosion can be minimized with water treatment such as maintaining a neutral PH level, but no piping will last forever and will eventually need to be replaced.

Inadequate Flow

Flow into a catch basin, manhole and through piping should be smooth. Using water from a hose, test out the system. Get a good flow of water going through the most upstream catch basin and look for leaks or problem areas that should be fixed before the back-filling process. If there are issues with flow, this will need to be investigated and resolved before an inspection.

Piping Failure

Pipes could fail for several reasons. Common ones being poorly supported pipes lead to sagging and the loosening of clamps, bad workmanship, and manufacturer defects. Pipes will fail overtime due to wear and tear, internal and external corrosion and damage, and physical damage. These conditions can be detected with proper testing procedures.

Specifications, Codes, and Regulations

The BC Plumbing Code is intended to ensure the quality and functionality of plumbing systems and to protect the health of the occupants of the premises where a plumbing system is to be installed, as well as the health of the public in general. As a result of this intent, drainage and venting pipes are required by Code to be pressure tested after installation of each phase of the project.

The term authority having jurisdiction, commonly referred to as AHJ, covers a variety of regulating organizations. In our trade, the most common application is in reference to the building official responsible for Plumbing Code and regulation enforcement. For the building official, the limits may be the Building and Plumbing Codes adopted by the jurisdiction. Quite often, local AHJ may require a DWV installation to meet by-laws or regulations that address local conditions before they will give approval. Some examples of local regulations could include using piping materials that are suitable for local soil conditions, or the depth that piping must be buried to prevent freezing.

Return to Service

In accordance with the NPC, any design, installation, extension, alteration, renewal, or repair of a plumbing system must satisfy the testing requirements. Before returning a system to service you must ensure that it is properly tested.

Documentation

The procedure and requirements for a certificate of approval or passed inspection can vary widely from jurisdiction to jurisdiction and with the type of structure. Some projects may require certification from the installer that the plumbing system functions according to the approved design.

Now complete Self-Test 3 and check your answers.

Now complete Self-Test 3 and check your answers.

Self-Test 3

Self-Test 3

Media Attribution

- Figure 9. “Mandrel and mandrel test from manhole to manhole” is used for educational purposes under the basis of fair dealing.

- Figure 10. “Inflatable test ball and plug” by BCcampus is licensed under a CC BY-NC-SA 4.0 licence.

- Figure 11. “Corroded cast iron pipes” by thurdl01 is licensed under a CC BY 2.0 licence.