Competency A1: Install Medical Gas Systems

Learning Task 2

Lay Out a Medical Gas Piping System

The medical gas pipelines lead to many areas of the hospital, with the most vital area being surgery. Surgery and patient rooms are equipped with outlets that act as quick connections for attaching equipment and medical devices. Different configurations for the piping distribution system exist to link the source equipment to the terminal units. The chosen configuration should consider the acuity level of patients in different departments and the demand for medical gas from those patients.

Service requirements for different areas

The type of care given in different areas of a facility will dictate the specific gases and services that are required. The CSA 7396.1 Standard gives a suggested distribution guide used to direct the design professional in laying out the piping network (Figure 26).

| Area | Oxygen | Nitrous Oxide | Medical Air | Medical Vacuum | Nitrogen | Carbon Dioxide | AGSS |

|---|---|---|---|---|---|---|---|

| Anaesthetics | X | X | X | X | X | X | X |

| Autopsy | Blank | Blank | Blank | X | X | Blank | Blank |

| Clinical areas | X | X | X | X | Blank | Blank | X |

| Critical care | X | Blank | X | X | Blank | Blank | Blank |

| Emergency | X | Blank | X | X | Blank | Blank | Blank |

| Surgery | X | X | X | X | X | Blank | X |

Route piping

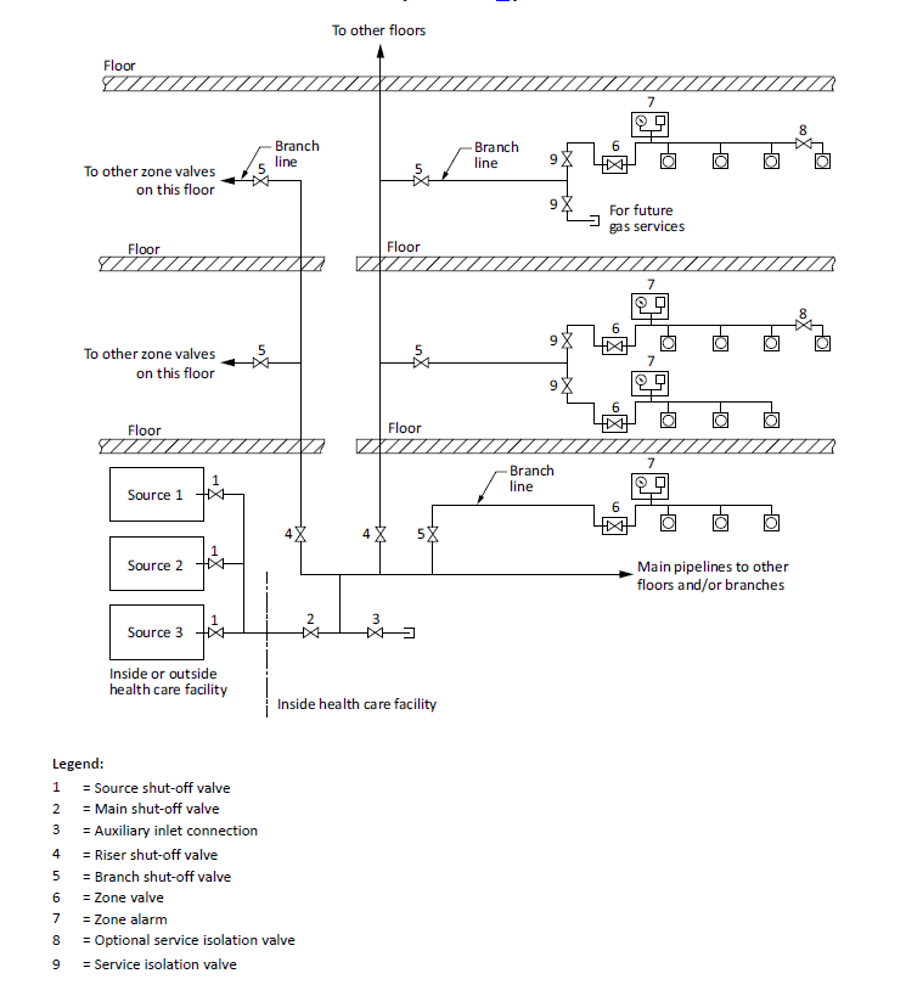

Figure 27 shows the terminology used for medical gas pipelines and shut-off valves. In general, outlets route to branch lines, branch lines will route to zone valves, zone valves must route via the branch to service valves at the main or riser, risers will route to riser valves, riser valves will route to the mains and the mains will connect to the main line valves. Records shall be made listing the location of each service isolation valve and the rooms or areas controlled by each service isolation valve. These records shall be stored in a secure manner and be accessible for reference by service and repair personnel.

A few general routing guidelines include:

- Piping should be configured to make the route as short as practically possible with a minimum number of fittings and turns (in particular medical vacuum).

- The more fittings and bends that are present in the pipeline, the greater the head loss for the medical gas. This means that the pressure drop in the line will be greater, ultimately affecting the end flow or suction the patient will be receiving.

- Wherever possible, route piping down hallways instead of through walls. If a wall only serves as a partition and does not reach the deck above, the piping can be run over the walls. Running lines through firewalls is not advised, as that will reduce the fire-stopping capability of that wall.

- For vacuum piping, avoid creating low spots or “U” traps in the route. The ideal vacuum layout would be sloped towards the pump inlet, to allow for any liquid to run off before reaching the pump. Of course, this is just an idealization and very difficult to implement practically. However, fluid drainage is definitely a consideration to keep in mind while creating pipe routes.

- It is standard practice for zone valves to run from the source into the left side and to the outlets/inlets from the right side. There are few circumstances where this orientation can be reversed and problems later on will not occur.

- Zone valves are to never be connected in series, so that shutting down one zone valve will force the shutdown of another. Each zone valve must separately run to a service valve. However, multiple zone valves may be feed from a single service valve.

Section 8 of the CSA Z7396.1 Standard lists the requirements for service isolation and zone valves. The following are some of the requirements that relate to the routing and location of these valves:

- All shut-off valves shall be accessible for servicing.

- There shall be an isolation shut-off valve between each supply system and the distribution system, located as close as possible to the supply.

- These valves shall be accessible to facility personnel.

- When the supply source is located outside the facility in an enclosure, a service isolation valve is required within the enclosure. This valve must be secured in the open position.

- Each riser connected to the distribution main and each branch connected to the riser shall have a service isolation valve installed. These valves shall be accessible to authorized persons only.

- There shall be at least one service isolation valve between the pipeline distribution system and any zone valve. The first service isolation valve upstream of the zone valve must be on the same floor as the zone valve.

- All service isolation valves shall be accessible to authorized personnel only.

- A zone valve shall be installed to control all of the terminal units in a specified zone.

- There shall be a zone valve between any terminal unit or group of terminal units and the upstream service isolation valve that controls them.

- A zone valve shall be on the same floor as the terminal unit(s) it controls.

- Zone valves shall not be installed in series.

- Zone valves shall be placed in locations where they can be seen and accessed

- Zone valves shall not be located in closets or locked rooms.

- Zone valves shall be installed immediately outside each anaesthetizing location.

- Zone valves shall not be installed closer than 2 m (6.5 ft.) to any fixed terminal unit.

- Zone valves shall be enclosed in zone valve boxes.

- Zone valve boxes shall be accessible at all times.

Areas not permitted

Generally, medical gas pipelines should be kept away from areas where an unsafe condition may exist. Specific areas where their installation is prohibited include the following:

- Kitchens or elevator shafts.

- A tunnel where contact with oil could occur.

- Exposed areas subject to damage unless protected.

- A service trench or tunnel, unless it is well ventilated.

- Underground, unless protected adequately against frost, corrosion and physical damage. Copper tubes may experience severe corrosion if buried in direct contact with certain aggressive environments.

- For buried pipe, a continuous warning system, such as warning tape, should be placed at one-half the depth of the burial.

Pipe sizing

Sizing of the pipeline distribution system should be carried out after the piping distribution system

routing through the building has been determined. The CSA Z7396.1 Standard states within Section 7.2 on pipe size design:

- Pipelines and fittings, including line pressure regulators, connecting assemblies, and low-pressure flexible hose assemblies, shall be capable of passing the maximum design flow of the pipeline distribution system at a nominal distribution pressure within the ranges given in Table 2. The pressure change shall remain within the limits given in Table 2. See Annex E for general guidelines for pipe sizes, flows, and pressure drops.

- The health care facility shall determine its medical gas flow requirements in consultation with technical and clinical staff, consulting engineers, and equipment suppliers.

The quoted Annex E of the CSA standard is supplied as a Medical gas pipe sizing guideline but ultimately the entire piping system must engineered for a minimum amount of pressure loss to ensure it meets the flow requirements for all of anticipated respiratory, anesthesia, and other diagnostic and therapeutic applications.

Pressure drop in the risers and main pipes should be kept below 2.3 Pa per linear metre (0.01 psi per 100 linear feet) of piping). This allows the risers and main pipes to act as reservoirs to accommodate the sudden spikes in demand in the piping system. The total pressure drop across the pipeline distribution system, excluding the terminal unit and its inlet connector, shall not exceed 35 kPa (5 psi) for compressed gases, except for nitrogen, which shall not exceed 85 kPa (12 psi). The pressure drop for vacuum shall not exceed 17 kPa (5 in Hg).

As a final precaution the pressure drop will be tested at each terminal unit when the system is commissioned.

Location of compressor systems

The area should have an average ambient temperature of 70oF (21°C) with a minimum ambient temperature of 40°F (4.4°C) and a maximum ambient temperature of 104°F (40°C). (Note: At temperatures below 32°F the bare compressor will not be adversely affected, but freezing of the condensate can occur which could affect operation.)

The systems should be located as close as possible to the point of usage to prevent excessive loss of operating pressure/vacuum due to friction pressure drop. Sound levels should be considered when locating the systems.

The compressor packaged systems should be placed to ensure easy access to perform maintenance and high visibility of indicators and gauges. It is recommended that a minimum space of 24” be allowed on all sides of the compressor systems for ventilation and maintenance. A minimum space of 36″ in front of the control panel is required by the electrical code. A vertical distance of 36” is required above the units for ventilation and maintenance.

Locations and limitations of cylinder and bulk supplies

There are particular requirements for storing medical gas cylinders and for bulk tank storage in health-care facilities.

Medical gas cylinders should be stored in a specifically built cylinder storage room or enclosure that allows the cylinders to be kept dry and in a clean condition. The storage room:

- Must be built of materials having a fire rating of at least one hour.

- Must have doors that open outwards and are lockable and accessible by authorized personnel only.

- Must be heated by low-temperature indirect means if required.

- Must provide electrical protection for electrical devices.

- Must be climate controlled so that the ambient temperature does not exceed 40°C (104°F) for any gas and is not be less than 15°C (60°F) for nitrous oxide and carbon dioxide.

- Must be well ventilated, with the vents located near the floor.

- Should have a means of separating empty and filled cylinders and labelling them as such, and have physical supports for the cylinders to avoid the risk of them tipping over.

- Should have good access for delivery vehicles and reasonably level floor areas.

Medical gas bulk storage systems must be located above ground if outdoors, or must be installed in a building or enclosure of non-combustible construction that is adequately vented and used for that purpose exclusively. Delivery truck access and signage are important considerations for these storage areas, as the tanks must be labelled in a very specific manner to warn building occupants of the safety hazards within.

Now complete Self-Test 2 and check your answers.

Now complete Self-Test 2 and check your answers.

Self-Test 2

Self-Test 2

Media Attributions

- Figure 27. “Medical gas pipelines and shut-off valves” – The source for this image is unknown. It is being used for non-commercial, educational purposes. To receive credit for this image, please reach out to the publisher.

Image Descriptions

Figure 27. “Medical gas pipelines and shut-off valves” image description: A labeled diagram illustrating the use of shut-off valves in medical gas distribution piping, highlighting the isolation points and key component locations through the different levels of a building.

- First Level:

- Tank Storage (1): External tanks are equipped with individual shut-off valves, allowing for the isolation of each tank.

- Main Supply Shut-off (2): Located immediately inside the building, this valve isolates the entire supply source(s) from the distribution system.

- Auxiliary Supply Shut-off (3): Positioned to isolate a backup gas supply, for uninterrupted service in case of primary supply failure.

- Riser Shut-off Valves (4): Each vertical riser has a dedicated shut-off valve to isolate specific sections of the system.

- Branch Shut-off (5): Any branch extending from a riser is fitted with a shut-off valve to allow for localized isolation.

- Redundant Zone Valve Shut-off (6): Installed to isolate a bank of terminal units, providing additional redundancy for enhanced safety.

- Zone Alarm (7): Positioned upstream of each zone, these alarms monitor the system to alert operators to any issues.

- Second Level:

- Service Isolation Shut-off (9): Positioned upstream of the zone shut-off, this valve allows for isolation of service lines feeding into the zone.

- Optional Service Shut-off (8): Installed downstream of multiple terminal units, this valve provides isolation for another group of terminal units, offering flexibility in maintaining the system. [Return to Figure 27]