Labour Costing

18 Factors Affecting Working Performance

In addition to sound human resource management, other factors influence the required amount of labour. These factors include:

- Menu items

- Use of convenience foods

- Type of service

- Quantity of meals and number of meal periods

- Facility layout and design and production equipment

- Work environment and number of hours worked

Menu Items

The number and complexity of menu items affects the production hours needed. If you have a menu with many items requiring difficult production techniques, you will require more preparation time per item. If your menu consists of a limited number of items requiring minimal preparation, you will require less time.

Use of Convenience Foods

Foods prepared on site require more preparation than similar menu items made with convenience foods, such as pre-portioned meats or desserts. You can reduce your labour costs by using convenience foods. However, you must consider two other factors: convenience foods can increase your food costs and may affect the quality of your product.

The second factor – affecting the quality of the product – is not always evident. Convenience foods made with high-quality ingredients and prepared exactly as recommended by the manufacturer can provide uniform portions of very good quality.

Type of Service

A restaurant featuring complex dishes with multiple components will require more labour than a cafeteria-style operation or a fast-food restaurant. Also, a restaurant that requires a higher level of skill to prepare complex dishes will require more experienced staff, which in turn means higher wages.

Quantity of Meals and Number of Meal Periods

The volume of business will affect the amount of labour required. Each restaurant will have a minimum staffing level without which it cannot operate. If it serves fewer people than this minimum staffing level can handle, the labour costs will be very high.

The number of meal periods can affect the productivity of the restaurant if different menus for each period require set-up and tear-down time. As well, different menus will usually mean a larger number of menu items, also affecting labour.

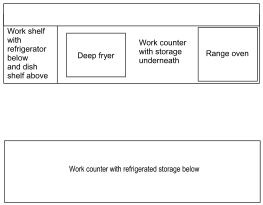

Facility Layout and Design and Production Equipment

Restaurant kitchens are often designed last, after all of the seating area has been designed. As a result, the space may be awkward and inefficiently laid out. To work efficiently, all work surfaces and storage areas required to produce an item should be located close together, as shown in Figure 27. This includes dry storage, refrigerated storage, freezers, storage for plates and glassware, work counters, grills, fryers, and ovens.

Poor kitchen layout can limit the number of individuals who can work efficiently. It may require time-consuming trips to distant storage areas to obtain food items or dishes. If the layout of the kitchen is too spread out, the minimum staff needed to operate each station may increase. For example, if a salad preparation station is located away from the main kitchen, you may require a salad preparation person even when the restaurant is not busy.

Production equipment such as mechanical peelers, choppers, and mixers can reduce the amount of time spent doing these tasks. The key in selecting the appropriate facility design and equipment is to match these parameters to expected volume of business. For example, if you purchase too large a mixer for the volume of business, the work involved in cleaning the machine after use will not warrant the extra expense of purchasing the equipment. On the other hand, too small a mixer will reduce efficiency as you will be unable to mix the quantities needed in a single batch.

Similarly, if your kitchen layout is very compact, you may be able to run efficiently with only one cook. However, you may be unable to meet the demands of a high volume of sales because the kitchen is too small to accommodate more than a couple of staff.

Work Environment and Number of Hours Worked

A hot, humid, noisy environment reduces comfort and increases stress and may negatively affect performance. Long hours and hard work without reasonable breaks can lead to reduced productivity. The same is true if you are understaffed. Not having enough staff means that everyone else has to work harder or for longer hours, resulting in tired staff and reduced productivity.

Productivity Standards

A first step in determining staffing needs is to establish productivity standards. These standards must take into account the amount of time necessary to produce food of the required quality. The standards are based on procedures dictated by standard recipes.

Productivity standards are measured in labour dollars or labour hours. Labour dollars measure productivity in terms of the number of dollars that must be paid out in labour to generate a certain revenue. The advantage of this approach is that budgets and financial statements are also expressed in dollars so comparisons can be easily made. However, it can be very time-consuming to calculate the labour dollars given different wage and salary scales. Labour hours must still be calculated because the number of hours determines wages.

Labour hours indicate the number of hours of labour needed to produce a given number of meals or generate a certain amount of sales income. When you use labour hours as a standard, it is less time-consuming to calculate. As well, some simple tasks may take the same amount of time to complete, whether they are performed by a chef or a dishwasher.

Determining Requirements

The productivity standard is determined by comparing number of labour hours scheduled to meals served or to sales income generated. It can be produced by department, by shift, by position, or by position and shift. More detailed standards make it easier to pinpoint problem areas and take corrective action. The most detailed is to prepare productivity standards by position and shift. This allows you to examine the efficiency of each staff member.

It makes sense to look at each position and shift. For example, a breakfast cook working with a limited breakfast menu and items that are easy to prepare can produce many more meals in a hour than the cook on your evening shift who has a large number of menu items with more elaborate preparation needed. Generally, more servers are needed than cooks for a given number of meals. Fewer dishwashers may be required. If only a single labour standard is developed for the restaurant, it will be harder to pinpoint problems with labour costs.

Staffing Guide

A staffing guide tells the manager how many labour hours are needed for each position and shift to produce and serve a given number of meals in the given restaurant. It incorporates the productivity standards. It tells managers what number of labour hours are needed for the volume of business forecast for a given meal period. The labour hours can be converted into labour dollars to establish standard labour costs.

The staffing guide serves as a tool for planning work schedules and controlling labour costs. The labour hours in the guide can be converted into labour dollar and standard labour costs by multiplying the labour hours for each position by the wage scale for that position. The staffing guide should be based on the performance of good employees. When scheduling new employees who have not completed an orientation training period, allowances will have to be made for their lower productivity.

This form of staffing guide is much more useful than industry guidelines that do not take into account the specific factors which affect the productivity in your workplace. It may still be useful to compare your staffing guide to other properties in order to assess how competitive you are.

An example of a staffing guide is shown Figure 28. Note that the staffing guide shows the minimum number of staff per peak service period.

Figure 28: Staffing Guide

| Type of Restaurant | Servers | Bus Persons | Chef or Sous Chef | Cooks | Dishwashers | Hosts |

|---|---|---|---|---|---|---|

| Coffee shop | 1 per 25 seats | 1 per 5 servers | 1 per shift | 2 per 65 meals | 1 per 100 meals | 1 per 10 servers |

| Casual dining room | 1 per 20 seats | 1 per 4 servers | 1 per shift | 2 per 50 meals | 1 per 65 meals | 1 per 8 servers |

| Formal dining room | 1 per 15 seats | 1 per 2 servers | 1 per shift | 2 per 40 meals | 1 per 65 meals | 1 per 4 servers |

Fixed Labour Costs

One factor that must be considered before developing a staffing guide is fixed costs. Fixed costs refer to the costs of running the operation that do not vary depending on the volume of business. For many businesses, the cost of the building, heating, lighting, insurance, and other similar costs are fixed. They do not change if the restaurant is busy or half empty. In fact, they continue even when the restaurant is closed.

Some labour costs are also fixed. If a restaurant has salaried employees, these costs are fixed and do not change depending on the volume of business. The business must pay the salary of these employees, even if the restaurant is not busy. In most restaurants, management positions, including the chef and sous-chefs, are salaried employees.

Variable Labour Costs

Variable costs must also be accounted for. Variable costs are costs that change based on the volume of the business. Food costs are the most obvious example of variable costs. Provided that the restaurant has not overstocked food, food costs will increase in a direct correlation with the volume of business. Labour hours above the salaried staffing levels are also variable costs. As the volume of business increases, hourly labour costs will increase proportionately.

Peak Periods

When the staffing guide is used to develop a staff schedule, the supervisor needs to consider the peak periods. For example, if the volume reaches 150 meals, 10.5 labour hours may be needed in the kitchen. An analysis of sales shows that the busiest period is between 6 p.m. and 9 p.m. The supervisor might schedule the cooks so that the first cook comes in from 4:00 p.m. to 9:30 p.m. and the second cook comes in from 6:00 p.m. to 11:00 p.m. This would ensure that there are two cooks available to prepare meals throughout the busiest period.

Scheduling Staff

The scheduling of staff is based on the labour hours needed to meet the projected sales volume. The supervisor also needs to keep an eye on labour dollars by considering whether staff on a lower wage scale could be scheduled. For example, on holidays or other times when overtime rates must be paid, it would be less costly to bring in a new employee who is not eligible for statutory holiday pay. Other factors to consider when developing schedules include the following:

- Staggered work schedules can be used to meet the demand over peak periods without incurring additional labour costs throughout the full shift.

- Part-time staff can be used to work short shifts of four or five hours to reduce overall labour costs.

- Full-time staff are usually used to cover all key administrative positions; sometimes full-time positions can consist of a mix of supervisory and front-line tasks in order to make up a full-time job.

- Temporary employees can be used to meet labour needs that are temporary in nature such as banquets, employee illness, or vacation relief.

- Legal considerations such as the requirements of the Employment Standards Act and provisions of the collective agreement must be kept in mind.

- Staff capabilities should be taken into consideration; some employees may thrive in a stressful dinner rush while others perform well under less stressful situations. Some employees may have additional skills (e.g., hosting, bartending), which can be used effectively when sales volume is low if collective agreements or staff policies permit.

- Employee’s preferences should also be accounted for in the schedule. Policies should be in place for requesting shift preferences or exchanging shifts between staff members.

No matter how well you have planned the schedule, problems can arise. A staff member may call in sick or fail to show up without warning. The volume of sales may be lower or higher than anticipated. You must have contingency plans to deal with these problems. You could have a staff member (or a casual employee) on call in case he or she is needed. You also have to know the capabilities of your staff. On a night when you have mostly experienced, capable servers and cooks who can handle stressful situations, you may be able to get by with one fewer staff than your staffing guide calls for.

When demand is lower than expected, you must know what limitations there are on sending staff home early, while still maintaining the minimum staffing needed to remain open. Of course, you must comply with collective agreements and all legislation that affects your workplace. If you understand the agreements and the Employment Standards Act well, you will know what flexibility you have to adjust to the situations that arise in the workplace.

Staying within Budgeted Labour Cost

A comparison of actual to budgeted labour costs can be used to plan future expenses. If your labour costs are higher than desired, you need to find ways to reduce them. One method of analyzing the labour costs is to look at the actual and budgeted labour cost percentage. The projected labour cost percentage is calculated by dividing labour dollars by the projected volume of sales. The actual labour cost percentage is the actual labour dollars spent for a given time period divided by the actual volume of sales.

Example 36

A small restaurant has the standard labour hours and rates of pay shown in Figure 29.

| Position | Labour Hours for 50 Meals | Labour Hours for 75 Meals | Labour Hours for 100 Meals | Hourly Rate (inc. benefits) |

|---|---|---|---|---|

| Food server | 8.5 | 12.5 | 16 | $9.85 |

| Bus person | 6.5 | 6.5 | 9 | $10.95 |

| Cook | 7 | 10 | 14 | $16.50 |

| Steward | 6.5 | 6.5 | 9 | $12.00 |

| Host | 0 | 0 | 4 | $10.25 |

Based on previous sales figures for a Tuesday night, the manager expected 77 customers on a particular Tuesday evening. The projected revenue for this evening was $1500.25. The manager developed a staff schedule based on the labour hours for 75 meals. The labour dollars were computed by multiplying the scheduled hours for each position by the hourly rate. The total labour cost for the evening was $437.30. The projected labour cost percentage was:

$437.30 ÷ $1500.25 × 100 = 29.1%

On this evening, the sales were down. Although 76 customers were served, very close to the number expected, the average cheque size was lower. Only $1425.95 worth of menu items was sold. The actual labour cost percentage was:

$437.30 ÷ $1425.95 × 100 = 30.7%

One of the best ways to improve productivity is to continually review and revise performance standards. Use the problem-solving process to identify the problem, generate alternatives, evaluate the alternatives, choose the best ideas, and implement them. Some questions you might ask yourself are:

- Can a particular task be eliminated?

- Is training needed to improve the skills of staff?

- Can a task be reassigned to a person who is not as busy (e.g., could the dishwasher assist with some pre-preparation of items early in the shift)?

- Can slow periods be utilized more effectively to prepare for high-volume times?

- Does the menu need to be simplified?

- Do menu or volume changes require changes in facility layout?

- Would convenience items reduce costs without reducing the required quality?

- Are the activities of another part of the operation affecting the performance of this department (e.g., the catering department has opened a new conference room some distance from the kitchen which requires food service)?

- Have there been changes in volume and peak times that need to be considered?

After considering all of these factors, you may still not be able to reduce your labour costs. You may have to raise your menu prices to improve the profitability of your operation. Of course, you need to consider the price the market will bear and the prices charged by your competitors before taking such an action.

It is often useful to look at both your food costs and labour costs when deciding whether a price increase is needed. If your labour costs are a little higher than anticipated and your food costs are lower, there may not be a problem. Some companies use a figure of 70% to 80% as a target for the sum of labour and food costs. Another strategy is to have lower contribution margins, but increase your volume. This makes sense because the more volume you have, the more money is contributed toward meeting your fixed costs of doing business.

Position Performance Analysis

Productivity standards are developed by considering the labour hours needed to perform assigned tasks. During a designated observation period, employees are asked to perform their jobs, adhering carefully to all established policies and procedures. They are carefully observed to ensure compliance. For example, cooks would be expected to follow all standard recipes, take scheduled rest breaks, and meet the required quality standards. This process of analyzing productivity is called a position performance analysis.

The employee is observed over several shifts. At the end of each shift, the supervisor completes a report, as shown in Figure 30, which indicates the name of the employee observed, the meal period considered, the number of meals prepared, number of hours worked, and number of guests per labour hour. The supervisor also records comments on workflow, adequacy of service, problems that arose, etc.

Figure 30: Position performance analysis

Position:

Name of employee:

| Shift | ||||

| Date | April 5 | April 6 | April 7 | April 8 |

| Number of meals served | ||||

| Number of hours worked | ||||

| Number of meals per labour hour | ||||

| Supervisor comments | ||||

| General comments |

Recommended meals per labour hour for this position: 30

Performance review by: Restaurant manager

Tools like this can help you identify the productivity of each staff member. Perhaps one cook is capable of producing 40 meals to the same standard in the time it takes another cook to produce 30. The first cook is more productive, and therefore a better choice to schedule on the busier evenings. You may also use this analysis to set goals and identify development options.

All in all, food costs and labour costs make up the bulk of the costs in running a successful kitchen. Having a solid understanding of both and how to manage them will be key in running a successful food service operation, whether it be a food truck or a major hotel.