Special Diets, Allergies, Intolerances, Emergent Issues, and Trends

19 Gluten-Free and Special Diet Baking Using the Critical Thinking Framework

Baking gluten-free products requires ingredient knowledge and an understanding of ingredient function in order to adapt existing baking formulas or to design new recipes. It is important to highlight that people with high levels of food allergies or food intolerances should be aware of Canadian labelling polices (covered earlier), and should take personal responsibility for informing themselves in order to decide which food products and growing and processing conditions can result in safe consumption. The same applies to bakers: they should be well informed of potential challenges with gluten-free ingredients and know the origin of their baking ingredients. More information is available under Co-Mingling in Agricultural Grain Products as a Possible Source of Food Allergens. A Canadian government website has useful information for Canadians with a soy allergy. If bakers are members of the Baking Association of Canada (BAC), they can refer to that organization, which is collaborating with Health Canada and the Canadian Food Inspection Agency (CFIA) on when to use food allergen precautionary labelling.

Beginning to bake gluten-free can be overwhelming when unfamiliar ingredients are being used, such as gluten-free flours, various gums, stabilizers, or emulsifiers. The Critical Thinking Framework (CTFW) is a tool that can be used in baking or product design to critically analyze finished products or solve problems. Figure 6 shows how interconnected each element (ingredient, method, and environment) is and how changing one element means the other two must also be considered to achieve a desired outcome.

When first learning how to bake gluten-free, it is vital to start by making simple products such as cookies, muffins, or simple cakes, using familiar ingredients. One of the first steps in designing a formula or recipe is to consider the texture required. Should the product be soft, chewy, or crunchy? Or should it be tender and moist? Using the diagram above, a baker should ask himself or herself the following questions:

- What are the functions of the ingredients used in a particular product?

- How is the environment contributing to the product (e.g., temperatures of ingredients or baking temperatures)?

- What method should be applied to obtain best results?

Once a product is finished, the next steps are:

- Investigate or examine the outcome of the product.

- Identify reasons for what has worked and what has not.

- Analyze the product and assess what can be improved or changed.

- Review the analysis and determine what discoveries have been made.

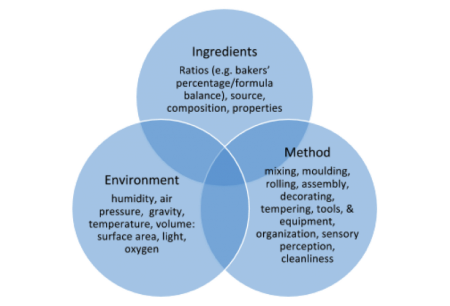

Figure 7 is intended to assist the baker in the continuous designing, trouble-shooting, improving, or perfecting of any baking formulas.

Using CTFW, it is possible to produce gluten-free products that are as tasty and satisfying as conventional wheat-based products. Moreover, bakers and food manufacturers need to consider their market when creating products to suit their customers’ needs. Besides applying the theoretical and practical knowledge, another key element in gluten-free baking is choosing good quality ingredients to produce great and nutritious products.

Gluten-Free Flours

There are a number of specially formulated gluten-free flours. The books Professional Baking (Gisslen, 2013) and Gluten-Free Baking (Richard & Coppedge, 2008) have a list of flours that are suitable for gluten-free baking. To become efficient and successful at gluten-free baking, it is advised that the baker make flour blends that can easily be mixed into a product. It is common for bakers to have flour blends for yeast dough products, biscuits, or fillings. Premixed flour blends and premade bases that include sugar, salt, or fats and that are formulated and standardized by bakers can improve efficiency and mitigate scaling errors. Fenster (2008) states that most of the flour blends she makes include sorghum (also called milo). Her blend consists of 35% sorghum flour, 35% potato starch/cornstarch, and 30% tapioca flour. This formula may lend itself well to some products but not to others. Other blends consist of flours with a high protein content and blends of nut flours that are high in fat content. The blending of the various flours is subject to the type of product desired as well as to the personal tastes and preferences of the consumer. Successful gluten-free baking requires commitment, adaptations, and improvements to baking formulas and methods. The baker must be patient and willing to perform many trials, and face those fraught with errors, in order to perfect and standardize gluten-free recipes.

Many recipes use volume measurements. While volume measurements work, the use of a balance or digital scale in either the imperial or metric weight version will provide more accurate yields. Attention needs to be given when converting volume measures to imperial or metric. Careful documentation of the conversions performed should be made so they can be referred to later.

Binding and emulsifying agents are widely used in gluten-free baking to give structure and stability to food products. These binding and emulsifying agents are often referenced as hydrocolloids and some resources include starches. Following are a few of the most used hydrocolloids in gluten-free baking. More information on these ingredients can be found in the Understanding Ingredients for the Canadian Baker and the Modern Pastry and Plated Desserts open textbooks. In gluten-free baking, hydrocolloids are used for binding or gelling purposes. They bind with free waters in products that are high in water activity (aw). It is best to calculate the weight of hydrocolloids in relation to the liquid used in a product.

Common Gums and Starches

Xanthan gum is a polysaccharide that can be made from various carbohydrates, most commonly from corn, by introducing a plant microbe called Xanthomonas campestris (Fenster, (2008). It is used as a thickener, stabilizer, emulsifier, and also as an ice crystal retarder and foaming agent. It can therefore be used in many gluten-free baking formulas because of its versatility.

Other hydrocolloids or binding agents used are guar gum and methycellulose. All of them increase stretchability and are used in doughs, mixes, or batters where extensibility is desired. Guar gum can be replaced with xanthan gum at a slightly higher amount as suggested by Fenster (2008). Methylcellulose is also used in egg-free baking, replacing egg whites. Locust bean gum is extracted from the kernels of the carob tree and the gum is similar to guar gum but has a lower viscosity and is thermo-irreversible. It is used in in ice creams, various dairy products such as yogurt, and in cream cheese to aid the spreadability. It is suitable in various gluten-free baking products.

Many other gelling or binding agents can be used, including pectin (vegetarian) and gelatin (animal derivative), which is available in powder or leaf form. Both pectin and gelatin are used in yeast doughs and mousses for stability. Agar can be used to replace xanthan gum and guar gum. Starches including tapioca, corn, and potato are used for thickening and to provide formation of structure.

Liquids

Liquid ingredients can vary from tap, distilled, or carbonated water to dairy milks, fruit juices, nut milks, and many non-dairy milks. Non-dairy milks include soy, rice, coconut, and others that can be used in non-dairy and nut-free diets.

Liquids are used to combine ingredients, soften doughs and batters, or assist gums and hydrocolloids in their gelling functions. Diamonds and Hemanson (2014) have proposed dividing the liquids into two categories, non-protein and protein-containing, to build a recipe. However, by using the CTFW approach, a baker would analyze the liquid, its consistency and properties (fluidity or viscosity), and examine the ingredients (e.g., if non-dairy milks are used). Many of these liquids contain thickeners, gums, and emulsifiers not acceptable to celiac, diabetes, or lactose-intolerant diets. Depending on the liquids used, a baker would have to anticipate their effect on other ingredients in a product. For example, if buttermilk is used, chemical leaveners would need to be adapted because buttermilk is acidic.

Leaveners in Gluten-Free Baking

Some leaveners contain gluten as a part of the production process. For instance, baking powder contains a starch. For gluten-free baking, it is important to know if the starch in the baking powder was made from non-gluten grains.

Yeast, an organic leavener, needs sugar to ferment and leaven and salt to control fermentation. For gluten-free yeast dough, xanthan gum or gelatin is commonly used to hold the structure so that carbon dioxide produced by the yeast is not lost during the fermentation and baking processes.

Commercial Flour Blends

For bakers who want a quick start in making gluten-free products but cannot invest the time to develop their own formulas and recipes, gluten-free flour blends are available from various suppliers such as Robin Hood. Their Nutri Flour Blend consists of rice flour with sugar beet fibre, potato, and tapioca starch. More information and access to recipes are available on the Robin Hood website, such as Robin Hood’s basic white bread recipe. Many flour blends include garbanzo bean flour, potato starch, tapioca flour, sorghum flour, and fava bean flour. Other gluten-free flour blends are sold by Highwood Crossing and are available in several local food stores and online. Pre-blended commercial flour combinations may not be cost-efficient and have other disadvantages because they may not lend themselves well to a variety of products.

Long Descriptions

Figure 7 long description: A diagram showing the factors that must be considered when designing and improving baking formulas. These factors are:

- Ingredients: ratios (e.g., bakers’ percentage/formula balance), source, composition, properties

- Environment: humidity, air pressure, gravity, temperature, volume, surface area, light, oxygen

- Method: mixing, moulding, rolling, assembly, decorating, tempering, tools and equipment, organization, sensory perception, cleanliness