Circuits

42 Anti-Plugging with Timers

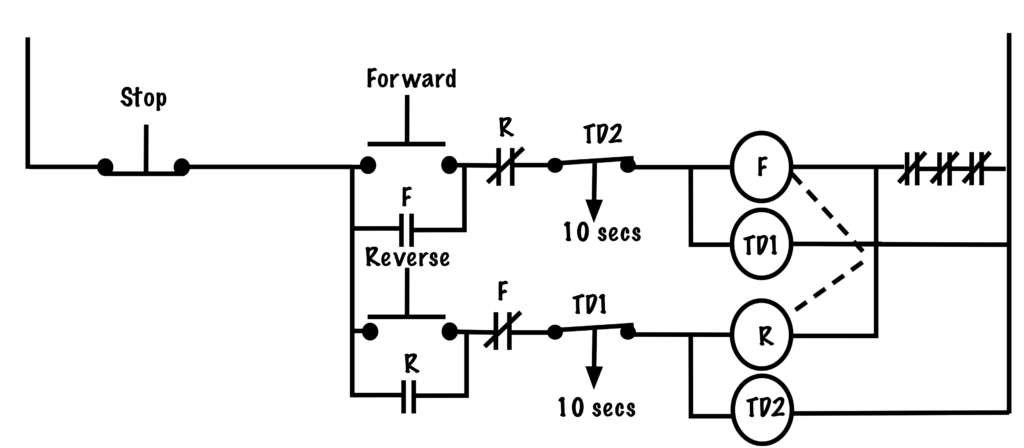

A forward/reverse circuit can use two off-delay timers to provide anti-plugging action in an anti-plugging circuit.

This circuit utilizes two off-delay coils to prevent the forward and reverse coils from being energized until ten seconds after the stop button has been pressed. This will give the shaft of the motor time to wind down to a halt and provide an anti-plugging feature for the circuit. To achieve this, the normal control circuit for a reversing magnetic starter is modified slightly by connecting an off-delay timer in parallel with each of the contactor coils.

This circuit utilizes two off-delay coils to prevent the forward and reverse coils from being energized until ten seconds after the stop button has been pressed. This will give the shaft of the motor time to wind down to a halt and provide an anti-plugging feature for the circuit. To achieve this, the normal control circuit for a reversing magnetic starter is modified slightly by connecting an off-delay timer in parallel with each of the contactor coils.

Similar to how the normally closed electrical interlocks are connected in the circuit, the normally closed timed to close (NCTC) contacts of the timer connected in parallel with the forward coil are connected in series with the reverse motor starter, and vice versa.

If, while the motor is not energized, the forward pushbutton is closed, TD1 and the forward starter will energize, and the motor will begin to spin in the forward direction.

If, while the motor is not energized, the reverse pushbutton is closed, TD2 and the reverse starter will energize, and the motor will begin to spin in the reverse direction.

If the motor is energized in the forward direction, the circuit arrangement ensures that for ten seconds after the stop button has been pressed, the motor cannot be sent in the reverse direction as the timed contacts will remain open. Nothing however prevents the motor from being sent in the forward direction again, as the timed contacts for TD2 remain closed.

If the motor is sent in the reverse direction, then stopped, TD2 will ensure that the operator must wait ten seconds before the motor can be sent in the forward direction.

Under normal operation, this circuit will provide low-voltage protection (LVP), and the motor will run in either direction until either the stop button is pressed, or an overload occurs.

A circuit that is not designed to suddenly stop or reverse a motor until the shaft has come to a rest.

In contrast to the Power Circuit, the Control Circuit consists of inputs, in the form of switches, pushbuttons or pilot devices, which when activated, can either directly, or through a magnetic motor starter, energize a load. The Control Circuit often operates at a lower voltage than the Power Circuit for safety and ease of installation.

In electrical terms, refers to a connection where current has more than one path to flow.

Loads connected in parallel will experience the same potential difference (voltage), but may draw different values of current depending upon their individual resistance.

Normally-closed contacts used in forward/reverse control circuits that prevent both directions coils from being energized at the same time.

In electrical terms, refers to a connection where current has only one path to flow.

Loads connected in series will have the the same value of current flowing through them, and share the total voltage between them. Switches and overcurrent equipment is connected in series with equipment to control and protect it.

A momentary contact device that has a built in spring to return the button to its normal position once release. Available with either normally-open, normally-closed or both sets of contacts.

Circuits with low-voltage protection will not automatically turn back on when voltage is restored following a power outage. Examples include the microwave or power tools.

A moderate and gradual rise in the value of current over a relatively long period of time that is caused by excessive amounts of current drawn by a motor due to too much load being put on the motor.