Leavening Agents

30 Yeast

Yeast is a microscopic unicellular fungus that multiplies by budding, and under suitable conditions, causes fermentation. Cultivated yeast is widely used in the baking and distilling industries. History tells us that the early Chaldeans, Egyptians, Greeks, and Romans made leavened bread from fermented doughs. This kind of fermentation, however, was not always reliable and easy to control. It was Louis Pasteur, a French scientist who lived in the 19th century, who laid the foundation for the modern commercial production of yeast as we know it today through his research and discoveries regarding the cause and prevention of disease.

Types of Yeast

There are several types of yeast.

Wild Yeast

Wild yeast spores are found floating on dust particles in the air, in flour, on the outside of fruits, etc. Wild yeasts form spores faster than cultivated yeasts, but they are inconsistent and are not satisfactory for controlled fermentation purposes.

Compressed Yeast

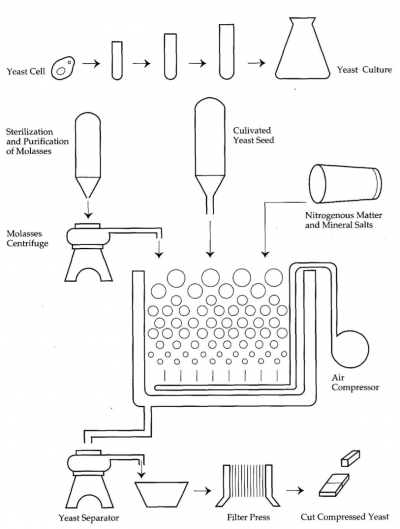

Compressed yeast is made by cultivating a select variety, which is known by experiment to produce a yeast that is hardy, consistent, and produces a fermentation with strong enzymatic action. These plants are carefully isolated in a sterile environment free of any other type of yeast and cultivated on a plate containing nutrient agar or gelatin. Wort, a combination of sterilized and purified molasses or malt, nitrogenous matter, and mineral salts is used to supply the food that the growing yeast plants need to make up the bulk of compressed yeast.

After growing to maturity in the fermentation tank, the yeast is separated from the used food or wort by means of centrifugal machines. The yeast is then cooled, filtered, pressed, cut, wrapped, and refrigerated. It is marketed in 454 g (1 lb.) blocks, or in large 20 kg (45 lb.) bags for wholesale bakeries.

Figure 7 illustrates the process of cultivating compressed yeast, and Table 9 summarizes its composition.

| Component | Percentage |

|---|---|

| Water | 68% to 73% |

| Protein | 12% to 14% |

| Fat | 0.6% to 0.8% |

| Carbohydrate | 9% to 11% |

| Mineral Matter | 1.7% to 2% |

Active Dry Yeast

Active dry yeast is made from a different strain than compressed yeast. The manufacturing process is the same except that the cultivated yeast is mixed with starch or other absorbents and dehydrated. Its production began after World War II, and it was used mainly by the armed forces, homemakers, and in areas where fresh yeast was not readily available.

Even though it is a dry product, it is alive and should be refrigerated below 7°C (45°F) in a closed container for best results. It has a moisture content of about 7%. Storage without refrigeration is satisfactory only for a limited period of time. If no refrigeration is available, the yeast should be kept unopened in a cool, dry place. It should be allowed to warm up to room temperature slowly before being used.

Dry yeast must be hydrated for about 15 minutes in water at least four times its weight at a temperature between 42°C and 44°C (108°F and 112°F). The temperature should never be lower than 30°C (86°F), and dry yeast should never be used before it is completely dissolved.

It takes about 550 g (20 oz.) of dry yeast to replace 1 kg (2.2 lb.) of compressed yeast, and for each kilogram of dry yeast used, an additional kilogram of water should be added to the mix. This product is hardly, if ever, used by bakers, having been superseded by instant yeast (see below).

Instant Dry Yeast

Unlike instant active dry yeast that must be dissolved in warm water for proper rehydration and activation, instant dry yeast can be added to the dough directly, either by:

- Mixing it with the flour before the water is added

- Adding it after all the ingredients have been mixed for one minute

This yeast can be reconstituted. Some manufacturers call for adding it to five times its weight of water at a temperature of 32°C to 38°C (90°F to 100°F). Most formulas suggest a 1:3 ratio when replacing compressed yeast with instant dry. Others vary slightly, with some having a 1:4 ratio. In rich Danish dough, it takes about 400 g (14 oz.), and in bread dough about 250 g to 300 g (9 oz. to 11 oz.) of instant dry yeast to replace 1 kg (2.2 lb.) of compressed yeast. As well, a little extra water is needed to make up for the moisture in compressed yeast. Precise instructions are included with the package; basically, it amounts to the difference between the weight of compressed yeast that would have been used and the amount of dry yeast used.

Instant dry yeast has a moisture content of about 5% and is packed in vacuum pouches. It has a shelf life of about one year at room temperature without any noticeable change in its gassing activity. After the seal is broken, the content turns into a granular powder, which should be refrigerated and used by its best-before date, as noted on the packaging.

Instant dry yeast is especially useful in areas where compressed yeast is not available. However, in any situation, it is practical to use and has the advantages of taking up less space and having a longer shelf life than compressed yeast.

Cream Yeast

Creamy yeast is a soft slurry-type yeast that is used only in large commercial bakeries and is pumped into the dough.

Yeast Food

Yeast food is used in bread production to condition the dough and speed up the fermentation process. It consists of a blend of mineral salts such as calcium salt or ammonium salt and potassium iodate. It has a tightening effect on the gluten and is especially beneficial in dough where soft water is used. The addition of yeast food improves the general appearance and tasting quality of bread. The retail baker does not use it much.

Image Descriptions

Figure 7 long description: Diagram of the production of compressed yeast. To cultivate compressed yeast, you first start with a yeast cell. That cell grows and is transferred from test tube to test tube until it becomes a yeast culture, which is depicted in an Erlenmeyer flask. Then, the cultivated yeast seed goes into an air compressor, along with nitrogenous matter and mineral salts, as well as molasses, which has first been sterilized, purified, and put through a centrifuge. The air compressor looks like a boxy machine with different-sized circles representing air bubbles and what looks like a long tube ending in a circle leading out of the main vat. The mixture passes through the air compressor, then goes into a yeast separator, which is a machine that stands on two legs and has a round vat with a spout coming out of it. What comes out of the spout and into a bowl goes through a filter press, which has two angled shapes at each end and thin lines in the middle, almost like an accordion. The filter press produces cut compressed yeast, which is depicted as rectangular prisms that look like chocolate bars. [Return to Figure 7]

Media Attributions

- Production of Compressed Yeast © Baking Association of Canada