Learning Task 3

Describe Gas Piping, Tubing and Hoses

There are many different piping systems available on the market only some of which are approved for gas installations. Section 6 of the Gas Code stipulates the approved materials.

Types of Piping Systems

Section 6 of the gas code identifies the following types of pipe, tubing and hoses as well as the approved methods for making connections.

| Type of material | Type of Connections |

|---|---|

| Steel pipe | Threaded

Flanged Press-connected Welded |

| Copper tube | Brazed

Flared Compression Press-connected |

| Steel tube | Flared

Compression Press-connected |

| Polyethylene | Fusion

Compression slip-lock |

| Corrugated stainless steel tubing (CSST) | Manufacture specific self-flaring fittings |

| Corrugated metal connectors | Flare coupler |

| Hose connectors | Flare coupler

Quick-Disconnect Swivel coupling |

The Gas Code recognizes that as new materials are developed they would not be identified yet. Therefore the code stipulates that materials not specified in clause 6.2 of the Gas Code may be used if they conform to a nationally recognizes standard or to a test report of a nationally recognized certification organization.

Steel piping

Steel piping is also commonly referred Carbon steel or black Iron pipe. Steel pipe must conform to ASTM A53/ A53M of ASTM A106 pipe specifications. Steel pipe used for gas systems must have a wall thickness of either Schedule 40, Schedule 80, or Standard weight depending on the application or size, as outline in clause 6.2.3 and 6.3.8.1 of the gas code. Hot dipped zinc coated pipe and fittings may be used.

Copper tubing

Seamless copper water tube approved for gas installations may be either Type G, K, or L. All of these types may be used above ground provided they do not exceed 1-3/8″ OD size. Copper tubing is available is soft annealed coils or hard drawn straight lengths.

Type G copper tube is manufactured to the ASTM B837 Standard Specification for Seamless Copper Tube for Natural Gas and Liquified Petroleum (LP) Gas Fuel Distribution Systems, and is available in a range of outside diameter (OD) sizes.

Type K and L copper tube are manufactured to the ASTM B88 Standard Specification for Seamless Copper Water Tube and is available in a range of nominal sizes. The actual OD size of Type K and L nominal tube size is 1/8″ larger than its nominal size. This is important to know as the flare fittings for all types of copper tubing are sized by the OD. The pipe sizing tables within the gas code book are also based on OD tube size.

If copper tubing is used for underground applications it must be soft annealed Type K. Manufactures also produce Type L or G, tubing with an external poly coating which as also approved for underground gas installations.

Steel tubing

Steel tubing is approved for use on gas systems, but is not used as commonly for gas appliance supply installations. Seamless cold drawn low-carbon steel tubing used for gas systems must conform to the ASTM A179/A179M standard specification.

Polyethylene

All plastic gas pipe, tube and fittings shall be made of polyethylene (PE) that complies with the CSA B137.4 standard. Polyethylene medium density gas pipe has a maximum pressure rating of 100 psi and typically comes in coils in a variety of sizes. Plastic pipe and tubing are only approved for outdoor underground applications and is used for distribution mains, house service lines and after the meter on premise underground lines.

Plastic piping and tubing shall be inspected before and after installation for defects such as cuts, scratches, and gouges. Damaged cylindrical pieces shall be cut out and replaced. Inspection shall be adequate to confirm that sound joints have been made. Joints in plastic piping and tubing shall be visually checked for evidence of poor bonding. Where inspection reveals defective joints, they shall be cut out and replaced.

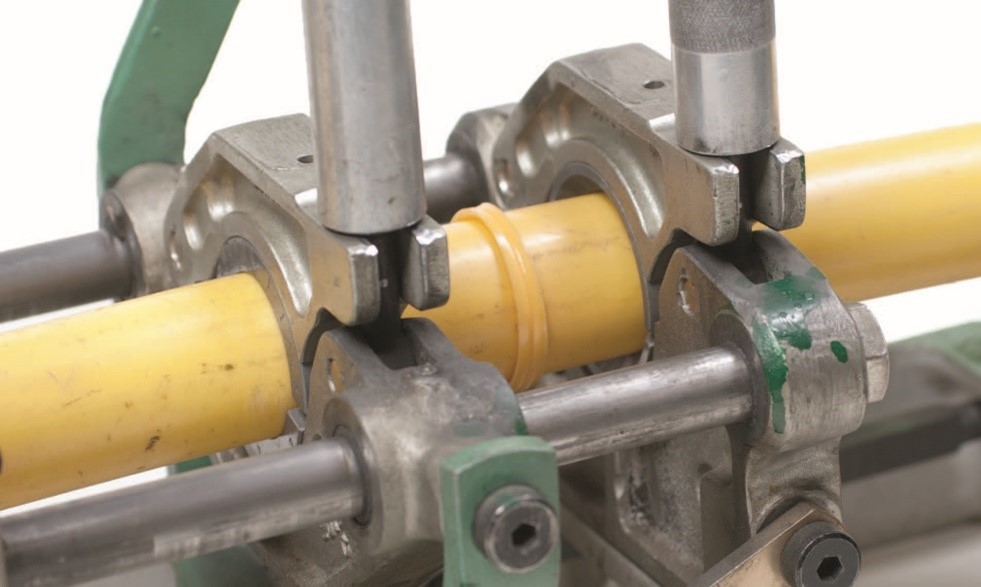

Polyethylene is a thermoplastic which softens when heated and solidifies when cooled, without any chemical reaction taking place. Polyethylene piping can be fused by applying heat and pressure. This is normally done with heating irons powered by electricity. The heating irons are used to heat the surfaces of the plastic pipe and fittings until the necessary temperature is reached. As the surfaces begin to melt, the heating irons are removed and the surfaces are pressed together and fused. Plain-ended piping is joined by butt-fusion (Figure 1), and fittings are typically socket fused, and tees are often formed by saddle fusion.

PE markings

In accordance with CSA B137.4, any polyethylene piping shall be clearly marked in a color which contrasts with the pipe, at intervals not greater than 1.5 m (4.9 ft), with the following information:

- the manufacturer’s name or trademark

- the generic plastic symbol

- the word “pipe” or “tubing” or the equivalent references “IPS” or “CTS”

- the minimum wall thickness, Standard Dimension Ratio (SDR), or Series Number of the pipe

- the date of manufacture or date code

- the nominal size of the pipe (NPS 2)

- the designation B137.4

- the word “Gas.”

There are many different grades of polyethylene (PE) used in plastic pipeline systems. Many of these materials are not compatible. As a result, each pipe is also marked with the grade of PE by way of a four-digit code. The first number of the code denotes the density of the pipe, the second number is the melt index rating, and the last two numbers indicate the design strength for density.

Corrugated stainless steel tubing

Flexible corrugated stainless-steel tubing is approved and available for installation on gas systems up to 5 psig. It is available in diameters of 3/8 in to 2 in, and typically comes in rolls of 250 ft (70 m) in length, but can be purchased longer coils depending on the size (Figure 2).

Corrugated stainless steel tubing (CSST) and associated fittings shall comply with ANSI/LC 1/CSA 6.26 or CSA publication CGA Certification Laboratory Requirement LAB-009.

Corrugated gas tubing is easily distinguished by a flexible yellow polyethylene jacket on the outside. Corrugated stainless steel tubing (CSST) will also be identified as such on the jacket itself. The general rule for CSST is that it must be installed in accordance with the manufacturer’s instructions. Before

installing CSST piping, you must first complete the manufacturer’s training program. The flexibility of CSST make it easy to weave through obstacles in one continuous run.

Corrugated stainless steel tubing manufacturers have also developed a lightning-resistant system, which will have a black jacket. The covering has a layer of metal mesh, designed to dissipate heat and electricity. The mesh is placed between two jackets of semi-conductive polymer. Fittings are designed to bite through the first layer of semi conductive polymer and into the metal mesh. This creates electrical continuity throughout the system, eliminating the need for manufacturer required bonding.

CSST may not be used as a gas connector. Although approved gas connectors may look similar to CSST their outside poly layer is actually a tighter fitting coating, not a loose jacket as with CSST.

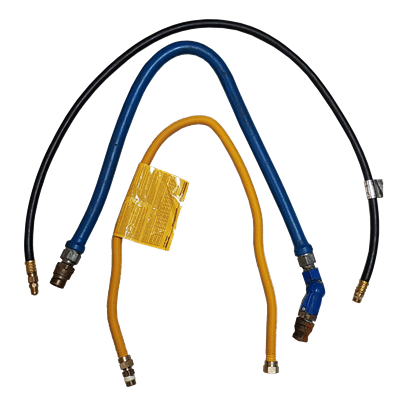

Gas Connectors

Gas connectors are factory-fabricated assemblies use to connect certain appliances, that require a flexible connection, to the ridged permanently installed gas supply piping or tubing. They may take the form of corrugated metal connectors or gas hose assemblies (Figure 3) depending on the application requirements.

The correct connector for the application depends on usage factors such as.

Will the appliance:

- have repeated movement after being connected

- have repeated disconnection and reconnection requirements

- be used outdoors

A gas connector shall be certified to ANSI Z21.24/CSA 6.10, ANSI Z21.69/CSA 6.16, ANSI Z21.75/CSA 6.27, or ANSI Z21.101/CSA 8.5. All hose and hose fittings must comply with CSA CAN/CGA-8.1 or CSA CAN1-8.3, and be rated for a minimum working pressure of 350 Psig (2,400 kPa).

A gas hose may be equipped with a quick disconnect device that has an internal automatic shut-off when disconnected (Figure 4). Quick disconnects must be certified to ANSI Z21.41/CSA 6.9.

Now complete Self-Test 3 and check your answers.

Now complete Self-Test 3 and check your answers.

Self-Test 3

Self-Test 3

- What is the name for the process of heat fusing the plain ends of PE pipe?

- End fusion

- Butt fusion

- Socket fusion

- Saddle fusion

- CSST tubing may be used as a flexible gas connector if the appropriate end adapters and Quick disconnect fittings are installed

- True

- False

- Copper tubing used for underground service (unless externally coated with PVC resin) shall be what minimum type

- Type L

- Type K

- Type G

- Type M

The answers for the following questions can be found in Section 6 of the B 149.1 Gas Installation Code.

- A certified flexible gas connector, used to connect an unvented appliance, must not exceed what length?

- 1 m

- 1.5 m

- 2 m

- 3 m

- What type of gasket is not permitted in a gas piping system?

- Nylon

- Teflon

- Neoprene

- Natural rubber

- Gas piping systems must be welded at what minimum size?

- 2″

- 2 ½″

- 3″

- 4″

- A quick-disconnect device shall not be used to connect appliances indoors in a residential building.

- True

- False

- Piping having a nominal diameter of less than NPS ½″ shall not be used underground.

- True

- False

- What is the maximum length of the Type I gas hose that must be used to connect a tube-type infrared heater?

- .6 m

- 1.05 m

- 1.5 m

- 2 m

Check your answers using the Self-Test Answer Keys in Appendix 1.

Media Attributions

- Figure 1 “Butt fusion” by Trades Training BC is licensed under a CC BY 4.0 licence.

- Figure 2 “Roll of ½″ CSST tubing” by Trades Training BC is licensed under a CC BY 4.0 licence.

- Figure 3 “Gas connectors” by Camosun College is licensed under a CC BY 4.0 licence.

- Figure 4 “Quick disconnect device” by Trades Training BC is licensed under a CC BY 4.0 licence.